Warehousing trends: automation, sustainability, and optimization

This article delves into the exciting changes on the horizon, encompassing automation, sustainability, and optimization. While sustainability and automation are the ultimate destinations, the present mandates a gradual, thoughtful transition. This exploration also highlights crucial steps and strategies for optimizing warehouses in the current landscape, emphasizing the need to reevaluate internal processes, enhance inventory management, and, ultimately, embrace automation as a means to streamline operations, reduce costs, and make more informed decisions.

Automation

Warehousing optimization is the future, but it is not a reality yet for all 3PLs. New processes recently implemented were only the first look at how warehousing management should be, with big data, AI, and robots involved. But before we get to this level of automation, 3PLs need to work on their structure and processes to avoid including basic mistakes in their programming.

Between the changes that we will see in years ahead, there will be:

- Robots in charge of managing merchandise

- Drones

- Automated inventories

- Big data

Sustainability

We have already spoken about sustainability in freight transportation, which is expected because of the importance that taking care of the environment has taken and to the industry reality since it generates 8% of greenhouse gas emissions in the world.

Electric cars, clean energies, and last-mile systems are not enough. We should look for warehouses designed under green practices. As well as automation, sustainability is the destination but not the present yet.

We do not need to apply all changes at the same time, but gradually. We could start with the following actions:

- Search warehouses close to urban areas and primary roads could reduce emissions.

- Use green materials in buildings.

- Prioritizing thermal isolation could save money and improve working conditions.

- Renew electric installations and make them sustainable.

- Certify sustainable processes with official organizations.

Optimization

In the last year, there was an increase in warehousing and distribution centers demand, related to the consumption of essential goods during the pandemic. Because of this, businesses increased their inventories and searched for new warehouses close to their distribution centers.

The first step to optimize warehouses is to review internal processes and make them as efficient as can be. With this, we prioritize efficiency, secure the fulfillment of the client’s needs and reduce costs without compromising quality.

Another important step is to analyze the inventory management strategy and improve deficient aspects. We should also amend workflows to improve the working environment and ensure the security of the place by providing extinguishers, identifying emergency exits, checking electrical installations, and determining how much space can be used. For this, you could ask for an external assessment that will measure the warehouse capacity and merchandise volume that can be held.

Process optimization and automation will allow you to know your organization’s health, reduce costs, and have all the information to make better decisions.

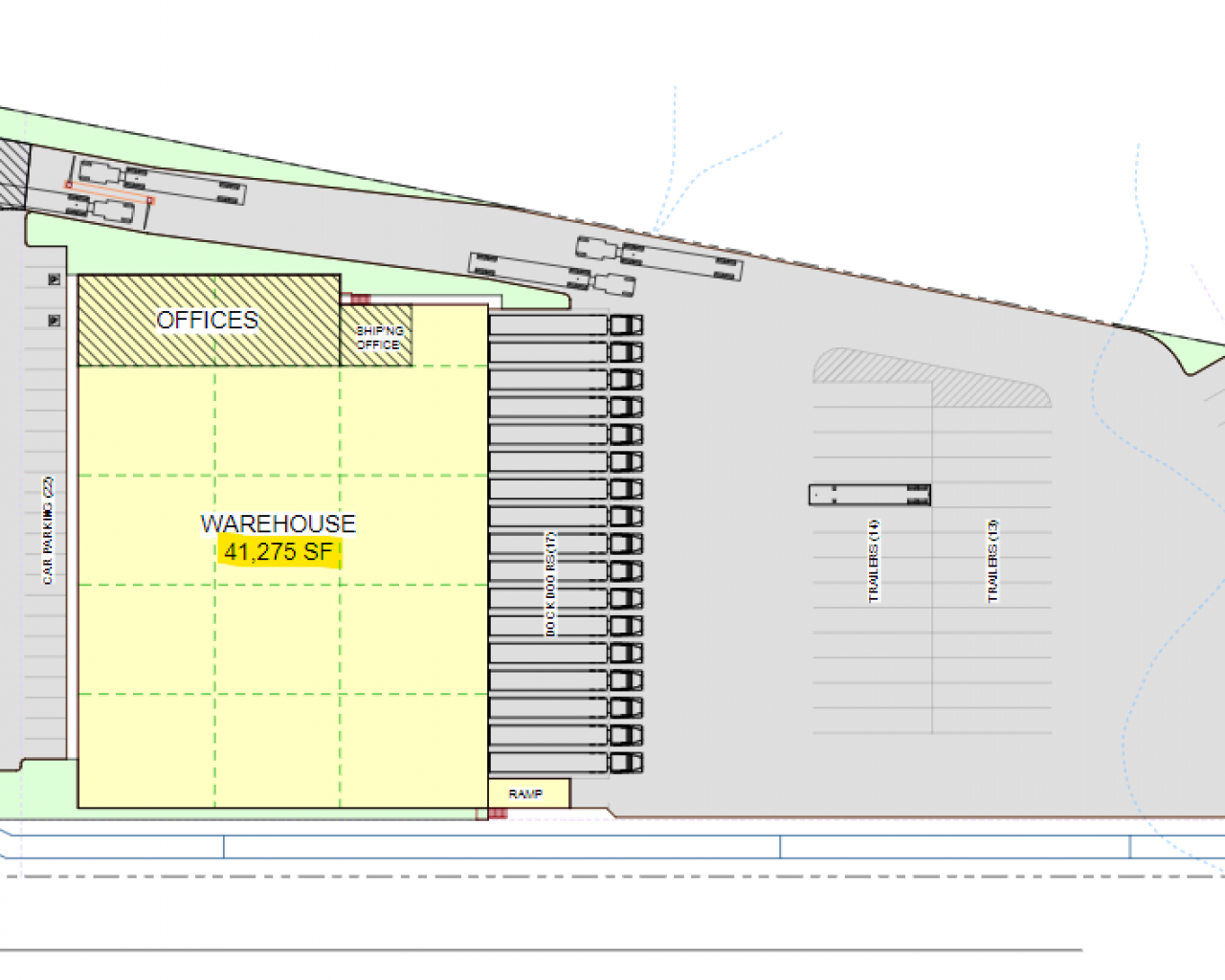

NEW WAREHOUSE COMING TO LAREDO …

We are thrilled to announce our most recent undertaking: the construction of a brand-new warehouse in Laredo, specifically designed to enhance our service capabilities. This facility will boast an expansive storage area covering 43,000 square feet and will feature 17 loading docks, further emphasizing our commitment to optimal service.

Outside Warehouse Image

Warehouse Docks Image

Constructions Warehouse Plans

Inside Warehouse

Custom-made solutions with Mexicom Logistics and Mexicom USA

Amongst the logistic services provided by Mexicom USA, you can also find bulk transshipment, palletized and with clamps, which are dedicated to electrical appliances, paper rolls, and big and fragile loads, such as fiberglass.

In case you need a quote for freight transportation, warehousing, or local movements in Laredo, get in touch with us, and we will design a custom-made solution for you.

Sources:

https://www.supplychaindive.com/news/building-sustainable-warehouse-shippers-cost-benefits/549625/

https://www.forbes.com/sites/stevebanker/2020/07/31/automation-is-the-future-of-warehousing/

Wonderful article! Your unique perspective on this topic is refreshing. I appreciate the valuable information you’ve shared