How manufacturers and retailers ensure OSA (On-shelf availability) and OLA (Online-availability) these holidays

The holiday season is a joyful time when retailers expect to see growth in their sales. This year, eMarketer forecasts that total US holiday retail sales will increase by 3.8%, while e-commerce sales are expected to have an increment of 13.2%. Of course, only retailers and manufacturers that have great management of their supply chain will see the fruits of this fortunate season by ensuring On-shelf availability and Online-availability.

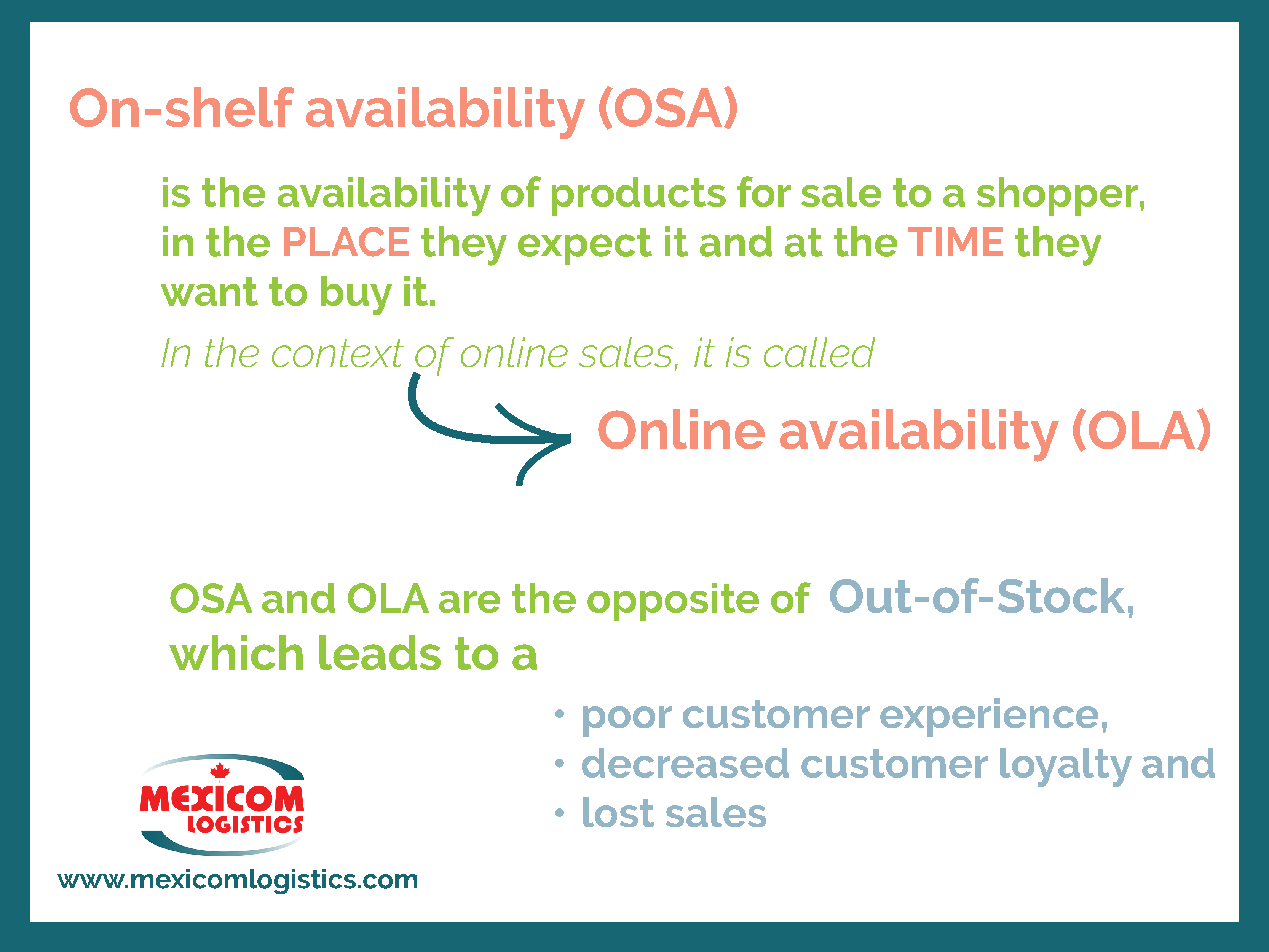

What are On-Shelf Availability and Online-Availability?

On-shelf availability (OSA) is the availability of products for sale to a shopper, in the place they expect it and at the time they want to buy it. Online-availability (OLA) is a metric that has the same meaning as OSA, but that is applied in the context of online sales.

Out-of-Stock is a problem that leads to a poor customer experience that results in decreased customer loyalty and lost sales. If the item is unavailable, customers will simply find a substitute. In the best case, customers will buy a different item, however, oftentimes, they will simply switch stores. This is true, especially during the holiday season. In this post, we share with you strategies that help manufacturers and retailers to ensure on-shelf availability and online-availability during the holiday season.

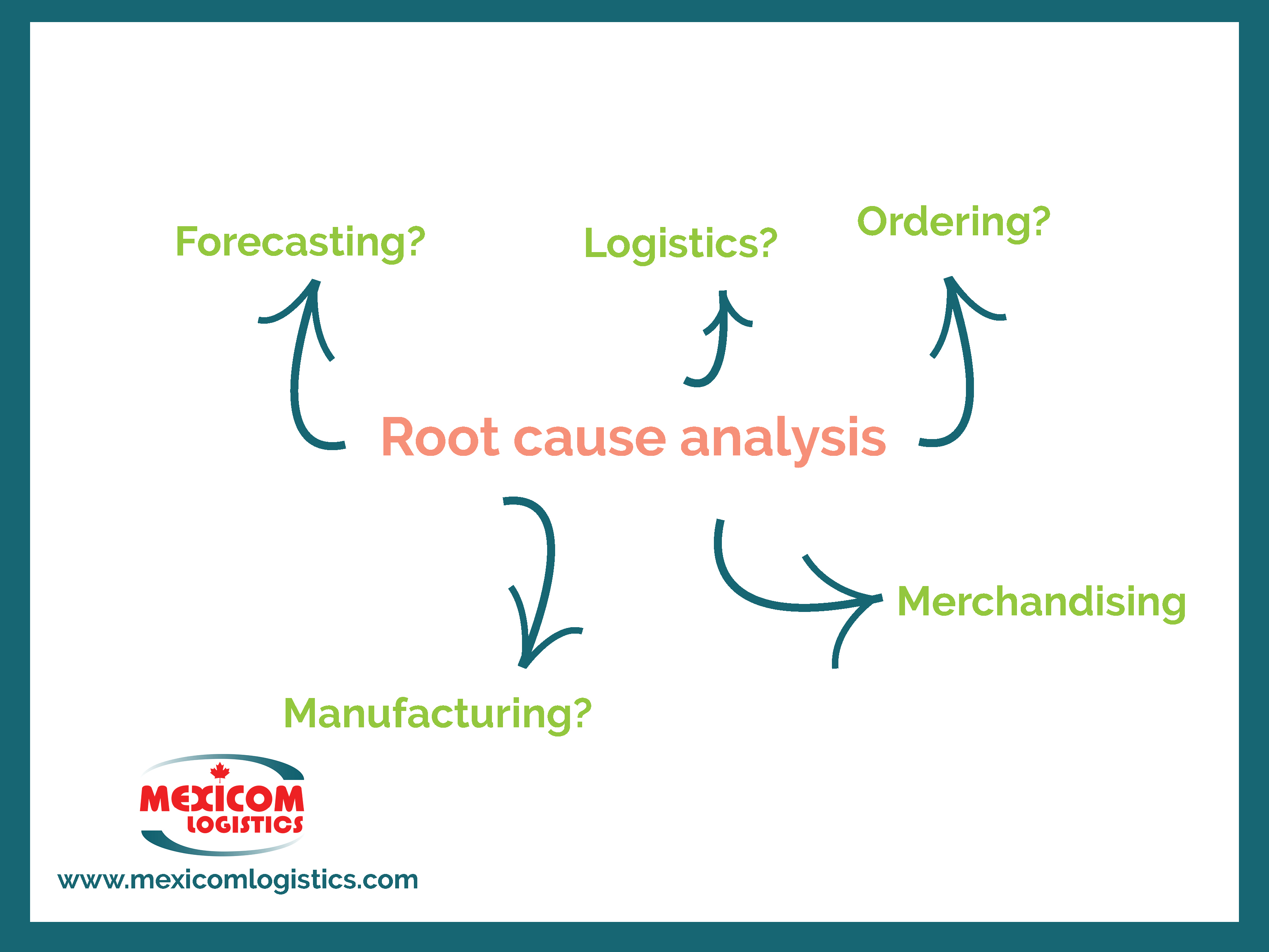

1- They understand the root cause that reduces on-shelf availability in their company

The first step to improve on-shelf availability during the holiday season is making a root cause analysis to identify what was the main cause of the out-of-stock problem during past years’ holiday seasons.

Can the main problem be a poor shelf monitoring at the store? Or is it an unexpectedly high demand for that specific product? Was the demand forecast accurate? Are there any theft issues? Is there a logistics or shipment error?

Successful retailers and manufacturers analyze the store execution, ordering, forecasting, manufacturing, merchandising and logistics areas to identify the root cause and develop solutions to the identified problems.

2- They implement an effective information flow within their supply chain

Manufacturers and retailers ensure consistent and accurate internal and external communication to make sure that their customers, suppliers and services providers share consistent information in the course of their interactions. During the Holiday season, it is crucial that all areas inside of your organization have fluent and accurate communication.

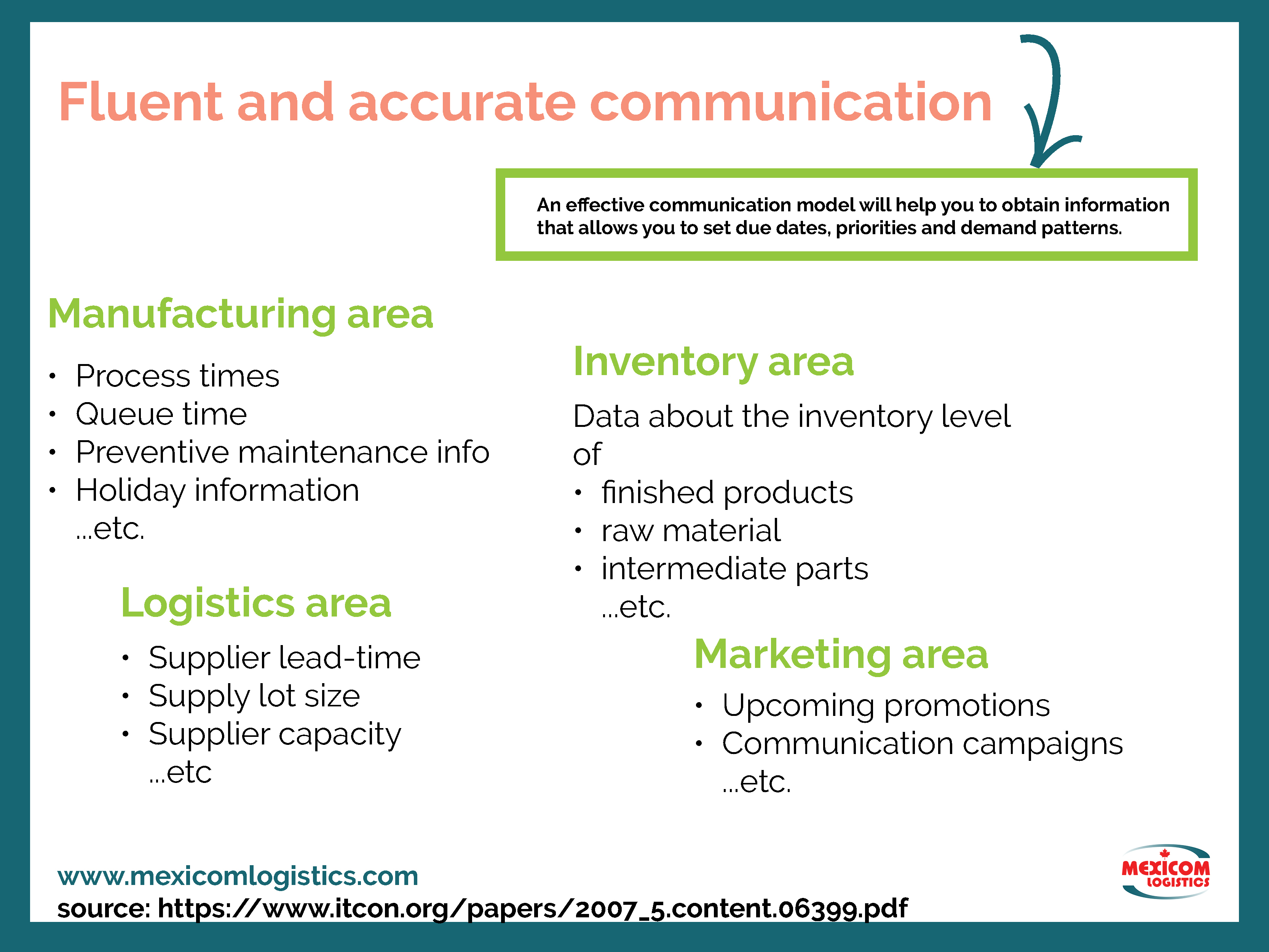

To implement an effective communication model, start by defining all data requirements from each area of your supply chain. What information do you need to know in order to ensure On-Shelf Availability and Online-availability?

The manufacturing area should provide clear information about process times, queue time, preventive maintenance information, holiday information, etc.

The inventory area should provide you data about the inventory level of finished products, raw material, and intermediate parts.

The logistics area of your supply chain should provide you with information about supplier lead-time, supply lot size, and supplier capacity.

The marketing area should provide information about upcoming promotions and communication campaigns.

An effective communication model will help you to obtain information that allows you to set due dates, priorities and demand patterns.

3- They apply an effective demand planning process

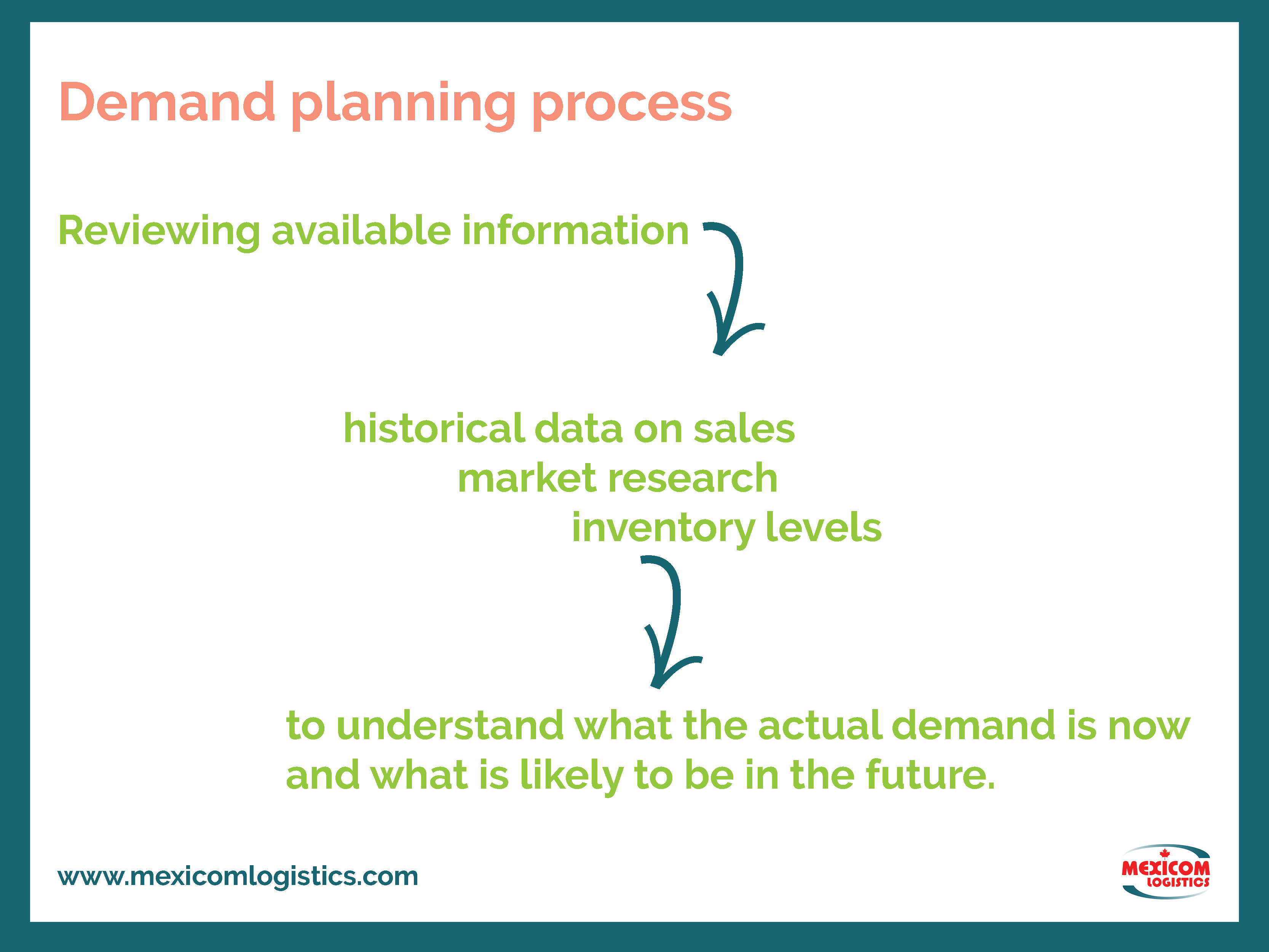

Demand planning consists of reviewing available information, such as historical data on sales, market research, and inventory levels to understand what the actual demand is now and what is likely to be in the future.

What are the strategies that retailers and manufacturers follow to implement effective demand planning during these holidays?

- They use previous years’ sales data to identify demand patterns and create demand forecasts.

- They ask directly to their customers whether they anticipate a greater demand for the upcoming holidays.

- Also, they incorporate sales and customers input, including promotions

- And they assess previous holidays assumptions

4- They understand the peak season logistics flow and implement strategies to get around

In North America, before the holiday season starts, there is a significant increment in shipments coming from China, which causes a rerouting on trucking transportation. For example, some carriers stop serving the route from LA to Laredo and start sending their trucks to big distribution centers in Dallas and Chicago. The rerouting causes a shortage of tucks availability to cover certain routes, which results in peak season prices and longer transit times.

Manufacturers and retailers in North America understand the logistic flows of the peak season and implement some strategies to ensure On-shelf availability and Online-availability. For example:

- They plan ahead and prioritize the shipment of products in higher demand.

- When possible, they implement cross-docking strategies to eliminate warehousing times.

- Ship with reliable freight forwarders that have a great network of carriers and will help them find the best solution to ship their peak shipments.

Recommended reading: 3 Supply chain metrics that really matter

Sources:

Click to access 2007_5.content.06399.pdf

https://www.thomasnet.com/articles/procurement/what-is-demand-planning/