3 Supply chain metrics that really matter

It is important to identify metrics that really correlate to success in your specific business. In this post, we present you 3 metrics that really matter to most companies and that help supply chain managers to track and assess their results.

Forecast Accuracy

Forecast accuracy plays a crucial role in attaining business goals. An accurate forecast can help you to reduce production overages and unnecessary inventory costs.

Forecast accuracy is the comparison between the actual demand value and the value stated in the forecast. There are many ways to measure if a forecast was accurate, for example:

Mean Absolute Percent Error or MAPE

Mean Absolute Error or MAE

Mean Square Error or MSE

Root Mean Square Error or RMSE

Error Total or ET

Mean absolute Deviation or MAD

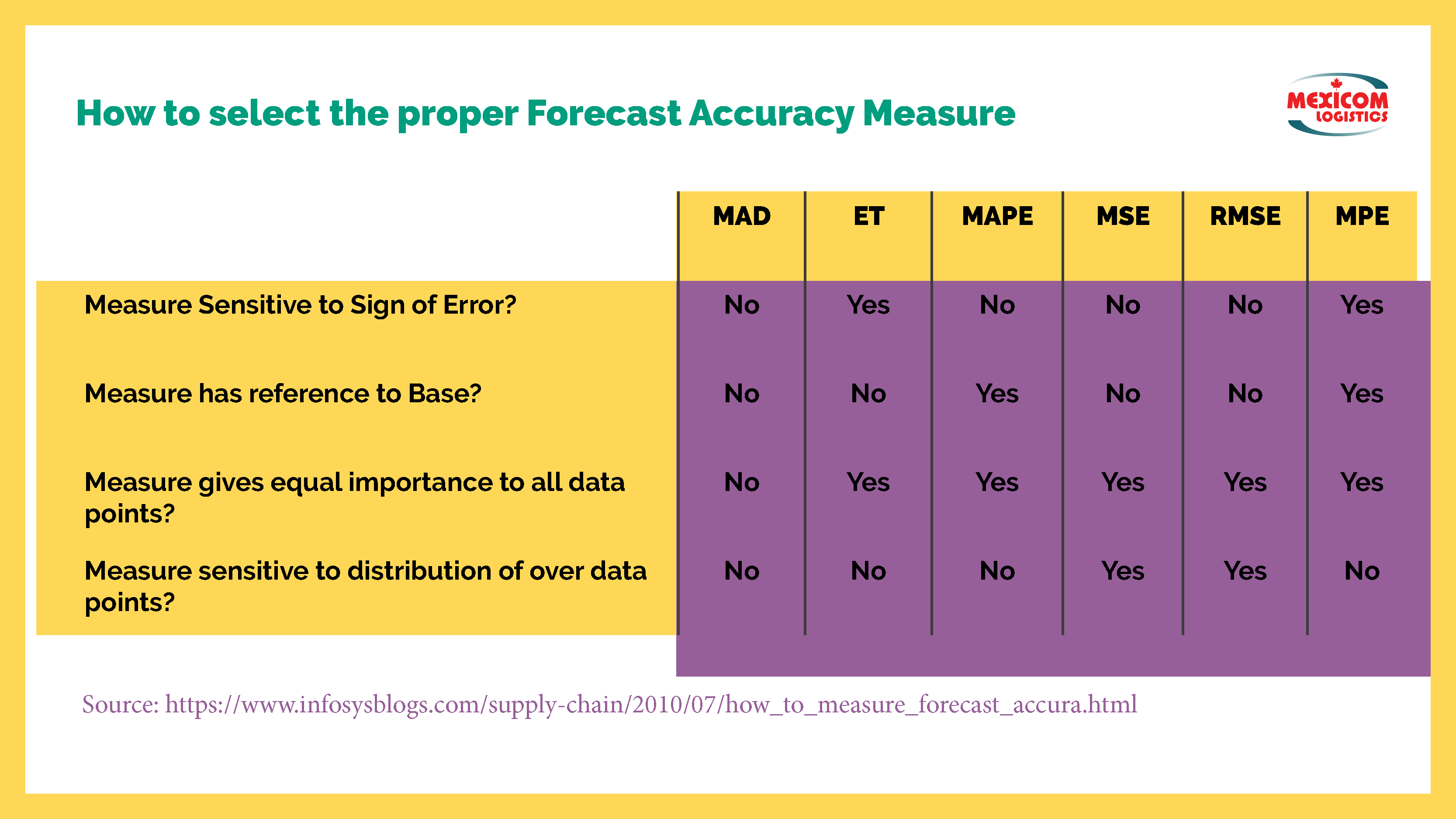

Not all measures are suitable for all businesses. The selection of the correct method to define forecast accuracy will depend on several factors. Nikhil B from Infosys presents a very useful table to help supply chain professionals to choose the metric that better suits their company.

Cash to Cash Time Cycle or Cash Conversion Days

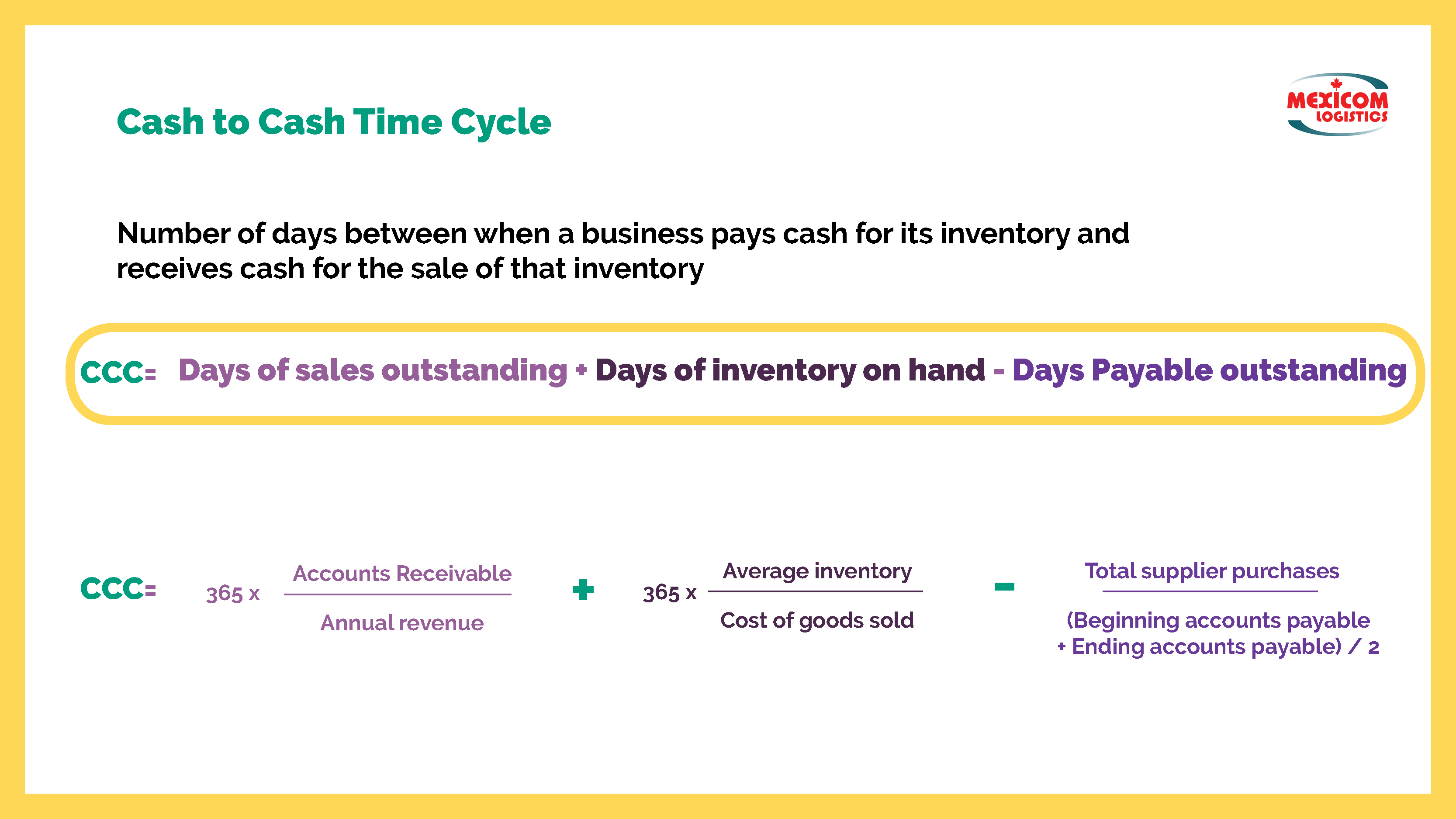

The formula to calculate the cash to cash tyme cycle is:

Days of sales outstanding + Days of inventory on hand – Days Payable outstanding = Cash to Cash Cycle

Days of sales outstanding expresses how many days after the sale it takes your customers to pay you on average. It is calculated like this: 365 x (Accounts Receivable/Annual revenue).

Days of inventory on hand refers to the time required to convert the inventory in sales. The Days of inventory are calculated like this: (Average inventory/cost of goods sold) x 365.

Days payable outstanding measures the number of days it takes you to pay your suppliers. The Days payable outstanding is calculated like this: Total supplier purchases ÷ ((Beginning accounts payable + Ending accounts payable) / 2)

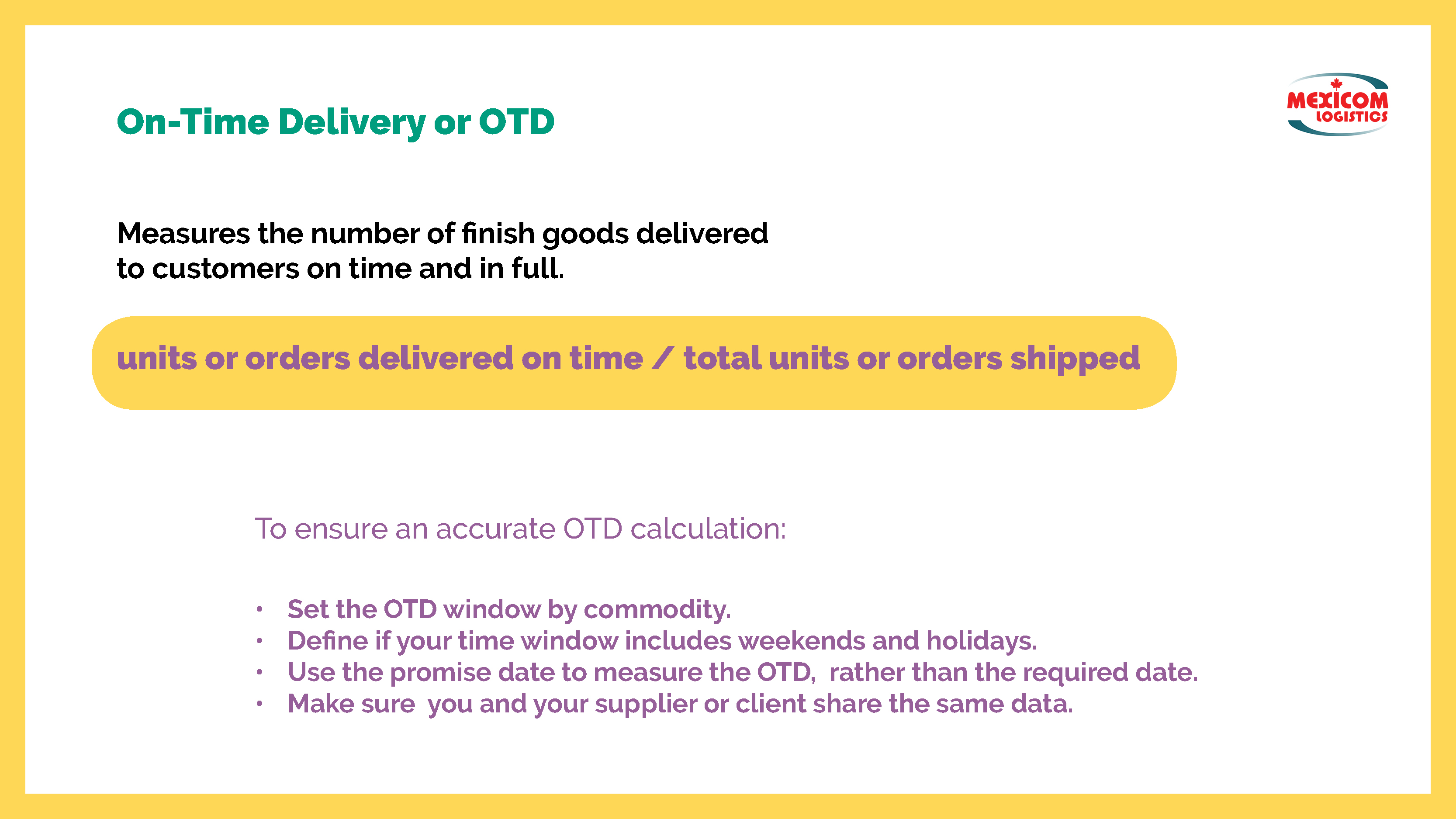

On-Time Delivery or OTD

This metric is also known as Delivery On-Time (DOT), On-time Performance (OTP) or Shipped On-Time (SOT) is a key metric that reflects the supply chain’s overall performance.

On-time delivery measures the number of finish goods delivered to customers on time and in full. It is calculated by dividing the units or orders delivered on time by the total units or orders shipped.

On-time delivery can be defined over different time windows. A typical OTD window is -5+0, which means: 5 days early, 0 days late. However, the OTD window depends on the type of commodity; it can be defined by hours, days or weeks.

To ensure an accurate OTD calculation, follow the following steps:

- Set the OTD window by commodity

- Define if your time window includes weekends and holidays.

- Use the promise date to measure the OTD, rather than the required date.

Sources:

https://www.infosysblogs.com/supply-chain/2010/07/how_to_measure_forecast_accura.html

http://blog.optimumdesign.com/on-time-delivery-defined

https://www.investopedia.com/terms/c/cashconversioncycle.asp

https://www.accountingtools.com/

Improve your On-time Delivery, contact Mexicom Logistics.

Your best ally to ship freight on time at the best rate.

+1 514-667-0174