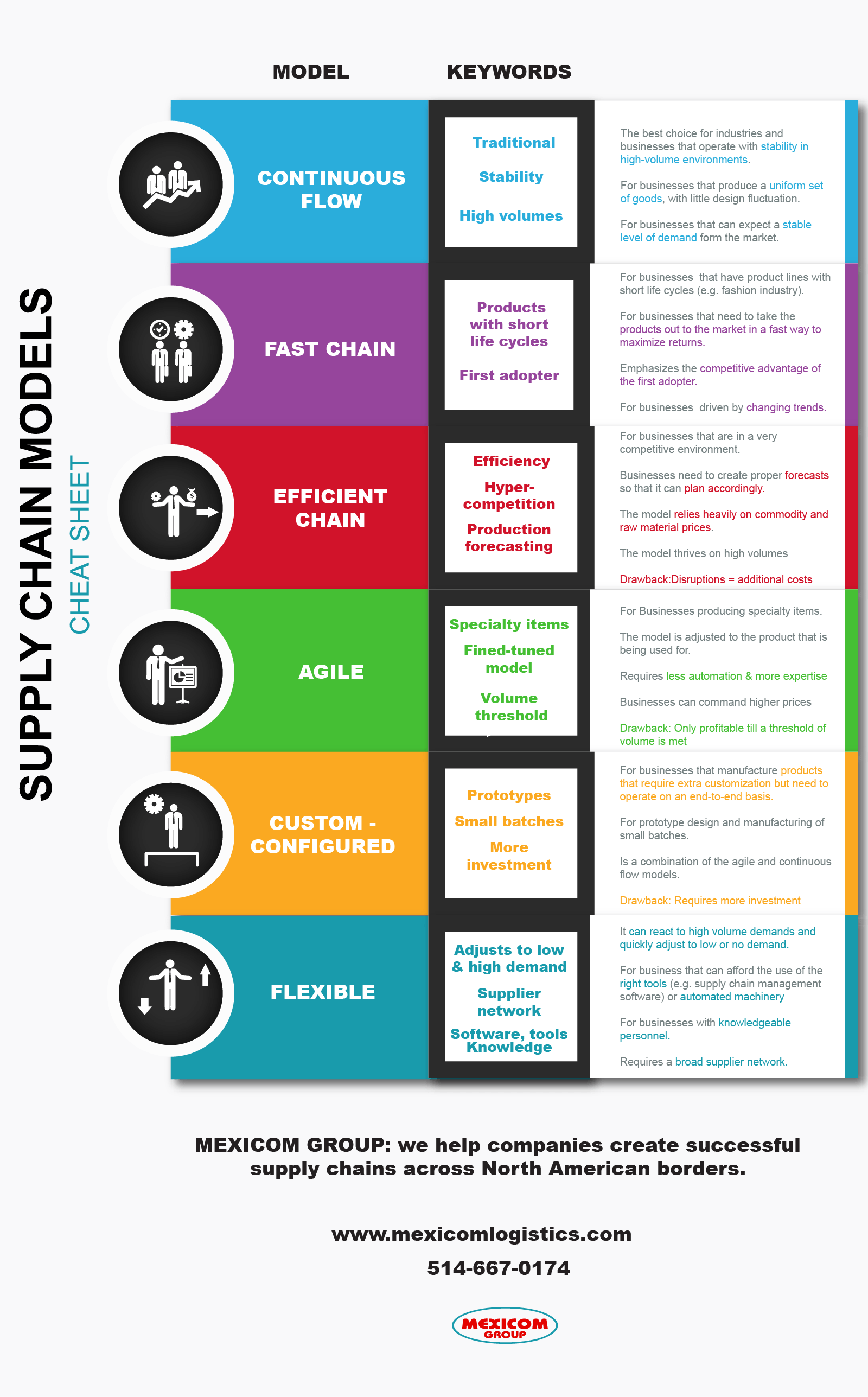

[Infographic] The 6 Supply Chain Models Cheat sheet

In the supply chain and supply chain management literature we can’t find an already accepted and extensive supply chain model that provides a comprehensive view of supply chain management. However, there are supply chain models that focus on specific aspects of the supply chain and that are of great use and importance. In this post, we present and explain the most important aspects of 6 Supply Chain Models that are widely used in the industry.

What are supply chain and supply chain management?

There are several definitions of supply chain and supply chain management. Some of them are more comprehensive than others.

First, let’s review some supply chain definitions:

“A structured manufacturing process wherein raw materials are transformed into finished goods, then delivered to end customers”. – Beamon B.

“Supply Chain is the group of manufacturers, suppliers, distributors, retailers, and transportation, information, and other logistics management service providers that are engaged in providing goods to consumers. A Supply Chain comprises both the external and internal associates for the corporate”- Chow, D. and Heaver, T

“Supply Chain as a set of entities (eg. organizations or individuals) directly involved in the supply and distribution flows of goods, services, finances, and information from a source to a destination (customer).“ – Mentzer, J., et al.

Now, let’s read some supply chain management definitions.

Supply Chain Management (SCM) is the “strategic and efficient coordination of the conventional business functions and the strategies across these business functions within a specific corporate and across businesses within a supply chain, for the aims of developing the long-term performance of the corporate and the supply chain as an entire.” – Christopher M.

“Supply Chain Management (SCM) aims at increasing value contribution to the customer while concurrently optimizing functional costs of the Supply Chain. – Little

“Supply Chain Management (SCM) is providing the right goods or services, to the right location, in the right quantity, at the right time and at the right cost” – Kitsolutions

One of the most precise and clearly expressed definitions of SCM is the one provided by Ph.D. Robert Handfield:

“Supply chain management (SCM) “is the active management of supply chain activities to maximize customer value and achieve a sustainable competitive advantage”

To know more about a comprehensive Supply Chain Management definition and the main supply chain activities, please read our post on the topic: What is supply chain?

As you can see, opposite to the supply chain definitions, supply chain management definitions add elements such as “strategic”, “efficiency”, “effectiveness”, “added value” and “competitive advantage”.

In order to perform effective management of the supply chain, build resilience to disruptions and mitigate exposure to various risks, Supply Chain Managers can make use of one of the supply chain models that we will present below. As each model has pros and cons, choosing the right model is a critical task.

6 Supply Chain Models

Continuous Flow

Keywords to remember: Traditional, requires stability

Use:

- Is the best choice for industries and businesses that operate with stability in high-volume environments.

- For businesses that produce a uniform set of goods, with little design fluctuation.

- For businesses that can expect a stable level of demand from the market.

The systems and the supply and demand in this type of supply chain management method are aligned so that a continuous flow of goods can be ensured.

Fast Chain

Keywords to remember: Products with short life cycles, first adopter

Use:

- For businesses that have product lines with short life cycles (e.g. fashion industry).

- For businesses that need to take the products out to the market in a fast way to maximize returns. This model emphasizes the competitive advantage of the first adopter.

- For businesses that are driven by changing trends.

Efficient Chain

Keywords to remember: efficiency, hyper-competitive industries, production forecasting

Use:

– For businesses that are in a very competitive environment.

– Businesses need to create proper forecasts so that they can plan accordingly, preparing machinery and raw materials.

– The model thrives on high volumes

– The model relies heavily on commodity and raw material prices.

Drawback:

Disruptions in production (e.g. raw material shortage) or in the sales cycles (e.g.demand swifts) can cause a ripple effect across the supply chain and ad additional costs.

Note: During and after the pandemic, businesses driven by the efficient chain model were the most affected due to labor shortages, material shortages, and delays.

Agile

Keywords to remember: specialty items, model fined-tuned for the product, expertise, threshold of volume

Use:

- For Businesses producing specialty items, which may require extra care in the supply chain.

- The model is adjusted to the product that is being used for.

- Requires less automation and more expertise to transport goods.

- Businesses can command higher prices for their products.

Drawback:

Only profitable till a threshold of volume is met. After that, it may prove costly to follow this model.

Custom – configured

Keywords to remember: custom setups, prototypes, and small batches, more investment

Use

- For businesses that manufacture products that require extra customization but need to operate on an end-to-end basis.

- For prototype design and manufacturing of small batches.

- Is a combination of the agile and continuous flow models.

Drawback: Requires more investment

Flexible

Keywords to remember: Adjusts to high and low demand, software, tools or automated machinery, personnel with knowledge base, broad supplier network.

Use:

- It can react to high volume demands during peak season and quickly adjust to a lean period on low or no demand.

- For businesses that can afford the use of the right tools (e.g. supply chain management software) or automated machinery for the job.

- For businesses with personnel who have the knowledge base to operate a flexible model with high efficiency.

- For businesses with a broad supplier network.

Sources:

https://www.icesi.edu.co/blogs/bitacoragestionsch1210/files/2012/10/A-New-Introduction-to-Supply-Chains-and-Supply.pdf

https://www.academia.edu/25214021/Supply_Chain_Management_Models_Applications_and_Research_Directions

![[Infographic] The 6 Supply Chain Models Cheat sheet [Infographic] The 6 Supply Chain Models Cheat sheet](https://mexicomlogistics.com/wp-content/uploads/bfi_thumb/dummy-transparent-qmy27ecj1ko1plcszcxguosvh2jrc880u5swuo0z3s.png)