Supplier Development part 1: Differences between Reactive and Proactive Supplier Development

The role of procurement has always been essential to attain the business vision and goals. But it is in recent times that companies have recognized proactive procurement as a component playing a major role to help organizations to prepare for the unprecedented uncertainties ahead and manage risks. The Assessment of Excellence in Procurement Research revealed that

“ 90% of the respondents agreed that Procurement’s strategic mandate and responsibilities have broadened to aiding the development and implementation of the organization’s strategies. There is a need for a more strategic responsibilities to achieve corporate growth.”

In this blog, we present the differences between a reactive and a proactive approach to Supplier development.

What is procurement?

Procurement is a key process that involves:

- Maintaining a continuous flow of supplies

- Effective and efficient management of the process of sourcing

- Suppliers selection and maintenance

One of the most important procurement goals is to develop a strategy that will guide the purchasing process and aligns with business goals.

Differences between Reactive and Proactive Supplier Development

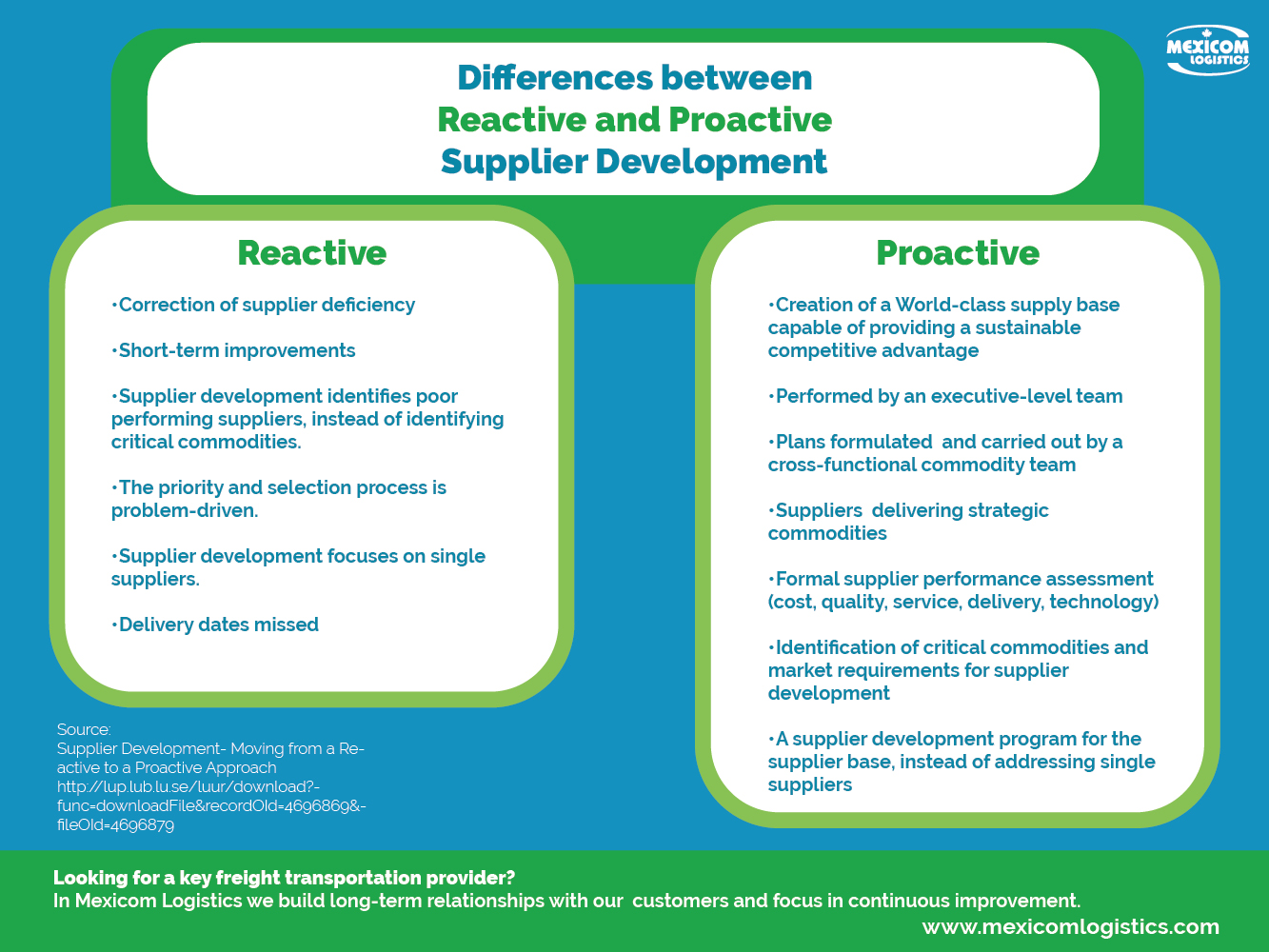

According to Krause, Handfield and Scannel, the main differences between reactive and proactive supplier development are as follows:

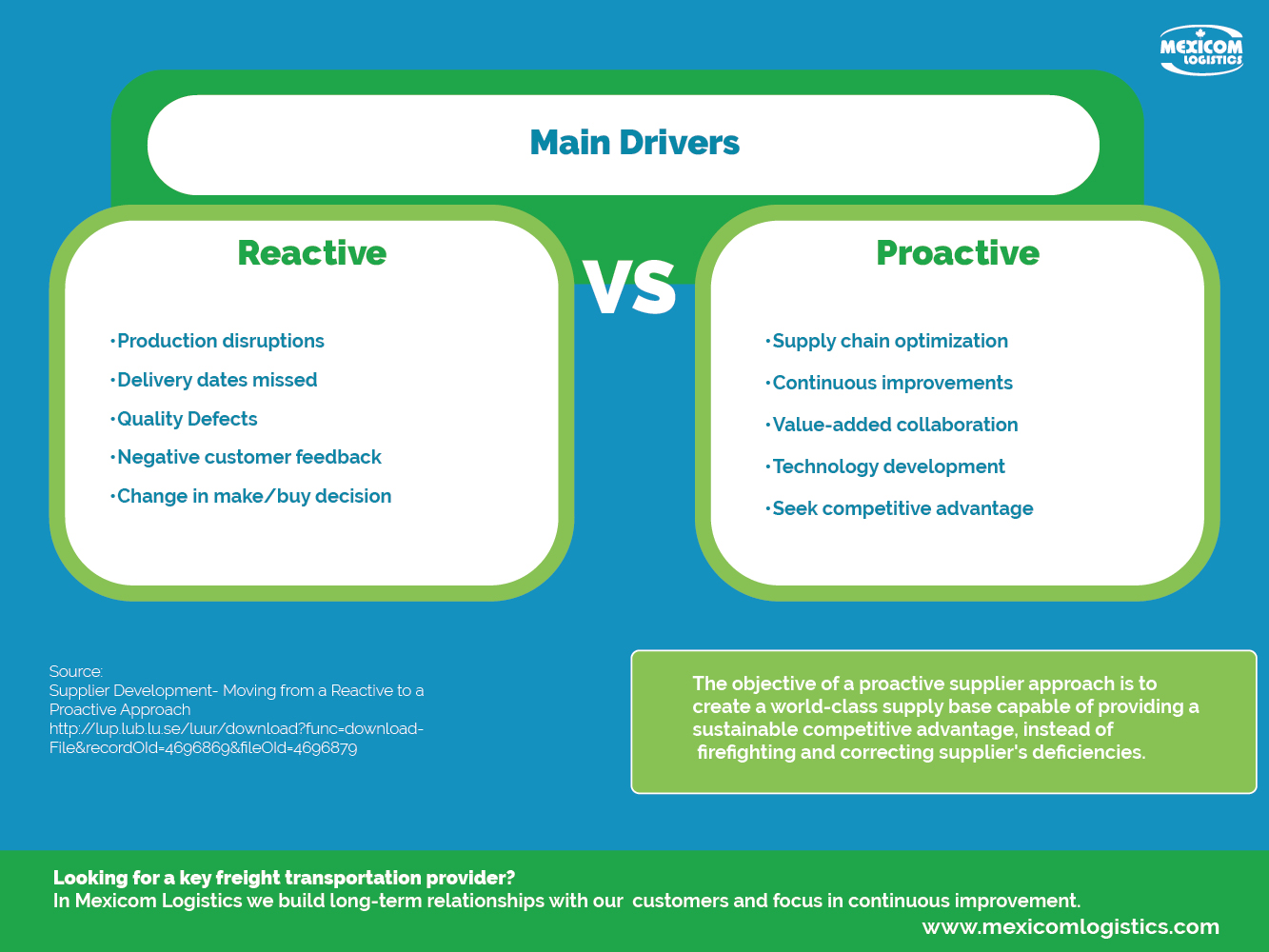

The objective of a proactive supplier approach is to create a world-class supply base capable of providing a sustainable competitive advantage, instead of firefighting and correcting supplier’s deficiencies.

Reactive Supplier Development

- Correction of supplier deficiency

- Short-term improvements

- Supplier development identifies poor performing suppliers, instead of identifying critical commodities.

- The priority and selection process is problem-driven.

- Supplier development focuses on single suppliers.

- Delivery dates missed

5 drivers of a reactive supplier development approach

1- Production disruptions

2- Delivery dates missed

3- Quality Defects

4- Negative customer feedback

5- Change in make/buy decision

Proactive Supplier Development

- Creation of a World-class supply base capable of providing a sustainable competitive advantage

- Performed by an executive-level team

- Plans formulated and carried out by a cross-functional commodity team

- Suppliers delivering strategic commodities

- Formal supplier performance assessment (cost, quality, service, delivery, technology)

- Identification of critical commodities and market requirements for supplier development

- A supplier development program for the supplier base, instead of addressing single suppliers

5 drivers of a proactive supplier development approach

1- Supply chain optimization

2- Continuous improvements

3- Value-added collaboration

4- Technology development

5-Seek competitive advantage

Sources

https://www.academia.edu/14626715/PROACTIVE_PROCUREMENT_AND_PURCHASING_STRATEGIC_OPERATIONS_FOR_A_COMPETITIVE_EDGE

http://lup.lub.lu.se/luur/download?func=downloadFile&recordOId=4696869&fileOId=4696879

Greetings My comment if we can get recognize in our small manufacturing company the solutions will meet the standard of working together we really need help leaders to meet demands practical training shortage lets feel that gap by working as a team .Be safe take care lets protect one another

Kind Regard

Da

Samuel