Warehousing Solutions: Choose The Right One For Your Business

In the dynamic landscape of logistics and commerce, warehousing solutions play a pivotal role in optimizing supply chains and ensuring seamless operations. A warehouse, defined as a dedicated space for the storage of commercial goods, helps form efficient distribution networks. Many warehouses offer a range of tailored solutions, but is it important to know which warehouse solution is the right one for your business as well as know the logistics partner with whom you will be working. Warehouse solutions can range from short-term storage to load consolidation, deconsolidation, and cross-docking. These services are designed to be the optimal choice for businesses seeking streamlined and effective warehousing operations.

Definition of Warehouse

A warehouse is defined as a facility dedicated to the storage of various commercial goods and materials. These spaces are utilized by manufacturers, importers, exporters, wholesalers, and shipping companies. Situated in industrial zones within cities and towns, warehouses are generally expansive structures. They commonly feature loading docks to facilitate the efficient loading and unloading of cargo from trucks.

In certain instances, warehouses are purposefully designed to facilitate the direct transfer of goods to and from border customs and different ports. To enhance the movement of goods within the facility, warehouses often incorporate specialized equipment such as cranes, forklifts, and liftgates. These equipment are typically stationed on loading docks and may run through the warehouse to further optimize the logistics of transporting goods.

Role of Mexicom USA Warehouse

Our warehouse, strategically situated in Laredo, TX, serves as a secure storage facility for commercial goods and customer materials. As a freight shipping company operating in the United States, we extend our facility space to accommodate the diverse needs of our customers. This includes manufacturers looking to import their commercial goods into Mexico, with the origin often being from Canada, and the other way around. Our facility offers a crucial space and the expertise necessary for safely unloading and loading cargo onto the trucks, facilitating seamless transportation between the three North American countries.

Here are some key benefits of warehousing:

In the business landscape, having access to warehousing solutions is beneficial for most businesses. Warehousing solutions offer a cost-effective means for businesses to store inventory. Especially when shipping commercial products, it is important to consider where the cargo loads will be transloaded. Having a warehouse that has experience in transloading benefits inventory from potential damage or loss. Also, it can be extremely beneficial to know the warehousing trends in order to choose the best warehousing solution for your business.

- Secure Storage: Warehouses provide a safe and secure environment for inventory and materials.

- Convenient Access: Warehouses provide easy access to transportation and shipping services.

- Cost Savings: Delegating all warehousing services to a third party proves to be cost-efficient in the long run. By refraining from intervening in an area that falls outside your business expertise, the company can focus on the core business realm, enhancing overall operational efficiency.

- Expanded Capacity: Warehouse flexibility to allow businesses to choose from different services offered.

The Importance of a Warehouse in Laredo, TX

The importance of establishing a warehouse in Laredo stems from the city’s strong economic emphasis on the transportation industry, and connectivity with the entire supply chain of North America.

Laredo hosts one of the longest-standing crossing points along the U.S.-Mexico border and is the largest inland port of entry in the U.S.

Laredo stands as the most substantial and efficient port of entry along the U.S.-Mexico border.

The Port of Laredo managed a total of 5,546,575 cross-border truck shipments in the year 2022.

In Laredo, logistics and transportation are the major contributors to its economic strength.

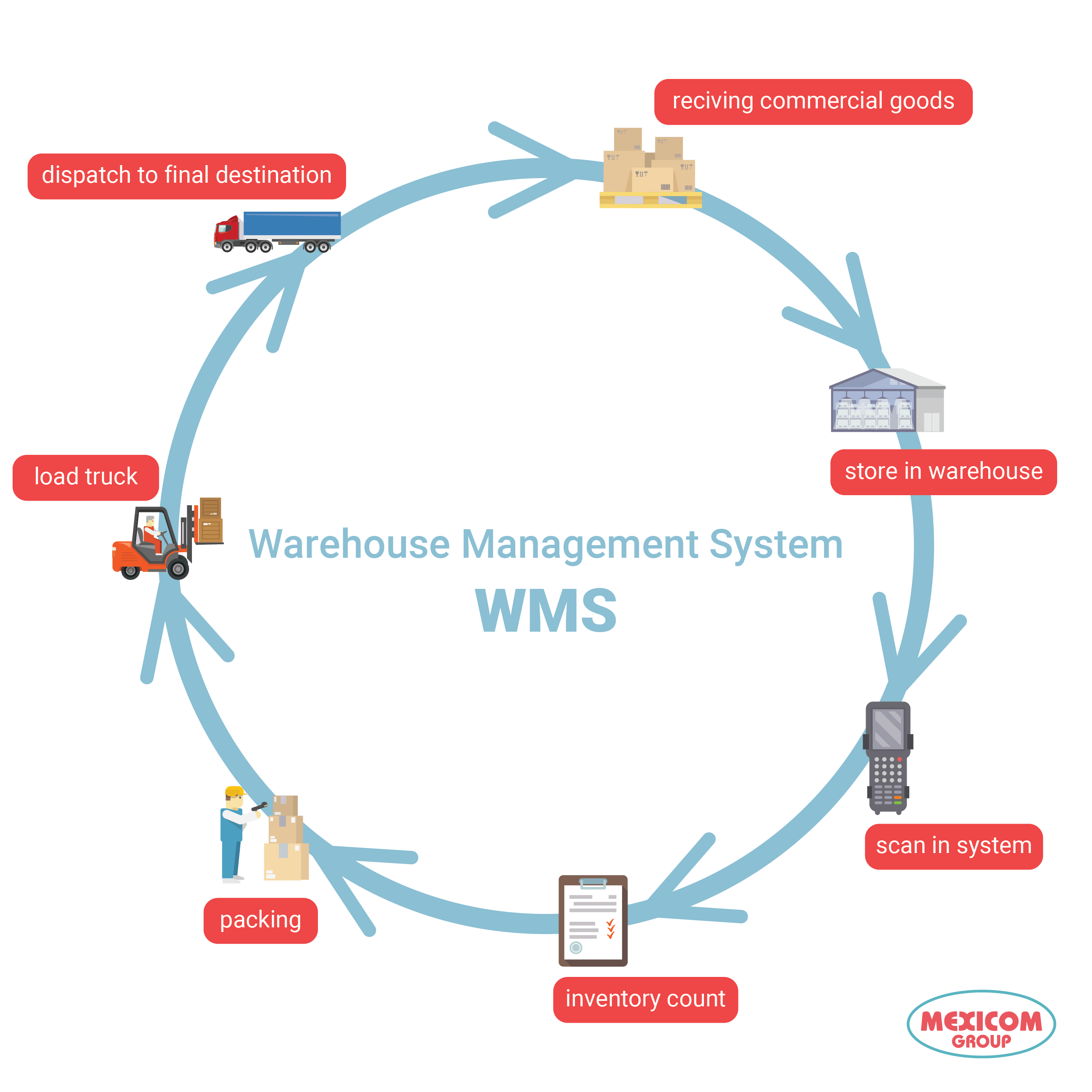

Warehouse Management System (WMS)

“WMS meaning: a warehouse management system is software that helps companies manage and control daily warehouse operations, from the moment goods and materials enter a distribution or fulfillment center until the moment they leave.”

“WMS use: It is used to help improve customer service levels, as well as reduce inventory levels and storage costs. In addition, a WMS can help to optimize the use of labor and other resources within the warehouse.”

Five benefits of a warehouse using the Warehouse Management System (WMS)

1. Enhanced operational effectiveness

- Warehouse Management Systems (WMS) systems try to minimize errors during the picking and shipping processes, eliminating redundant tasks, and fostering a more seamless workflow.

- WMS automates and optimizes various warehouse operations, spanning from receiving incoming goods to facilitating outbound deliveries. This results in heightened efficiency, streamlined processes, and increased capacity to manage larger volumes.

- WMS integrates data with Enterprise Resource Planning (ERP) and transportation management systems, offering a comprehensive perspective that extends beyond warehouse boundaries and accelerates the overall movement of goods.

2. Minimized expenses

- WMS can pinpoint items requiring priority when dealing with time-sensitive or perishable inventory.

- WMS optimizes warehouse space utilization, strategically placing inventory, and identifying the most efficient travel paths.

- Certain systems provide the development of floor plans and strategically positioning pallets, shelves, and equipment to operate at maximum efficiency, resulting in time and cost savings.

3. Real-time inventory tracking

- WMS system provides instant visibility into the movement of your inventory within, around, and beyond the warehouse.

- Employing barcoding, RFID tagging, sensors, or alternative location tracking techniques.

- The real-time insight generates more precise demand forecasts, implements a just-in-time inventory strategy, and enhances traceability.

4. Enhanced workforce management

- WMS enables accurate labor forecasting, schedule creation, efficient travel time optimization within the warehouse, and task assignment based on factors like skill level and proximity.

- WMS contributes to improved employee morale by fostering a relaxed, organized, and safe working environment where workers perceive their time as valuable and utilized effectively.

5. Enhanced relationships with customers and suppliers

- WMS leads to order fulfillment, expedited deliveries, and decreased inaccuracies for customers.

- It helps suppliers reduce wait times at loading bays and docks, contributing to improved relations.

How many warehouses in the U.S. use the Warehouse Management System?

A significant 83% of warehousing and logistics providers in the United States have adopted a WMS since 2021. These statistics unequivocally emphasize the system’s significance. To maintain competitiveness and relevance in the logistics industry, the integration of a WMS is becoming indispensable.

Choose the Right Warehouse Solution for Your Business

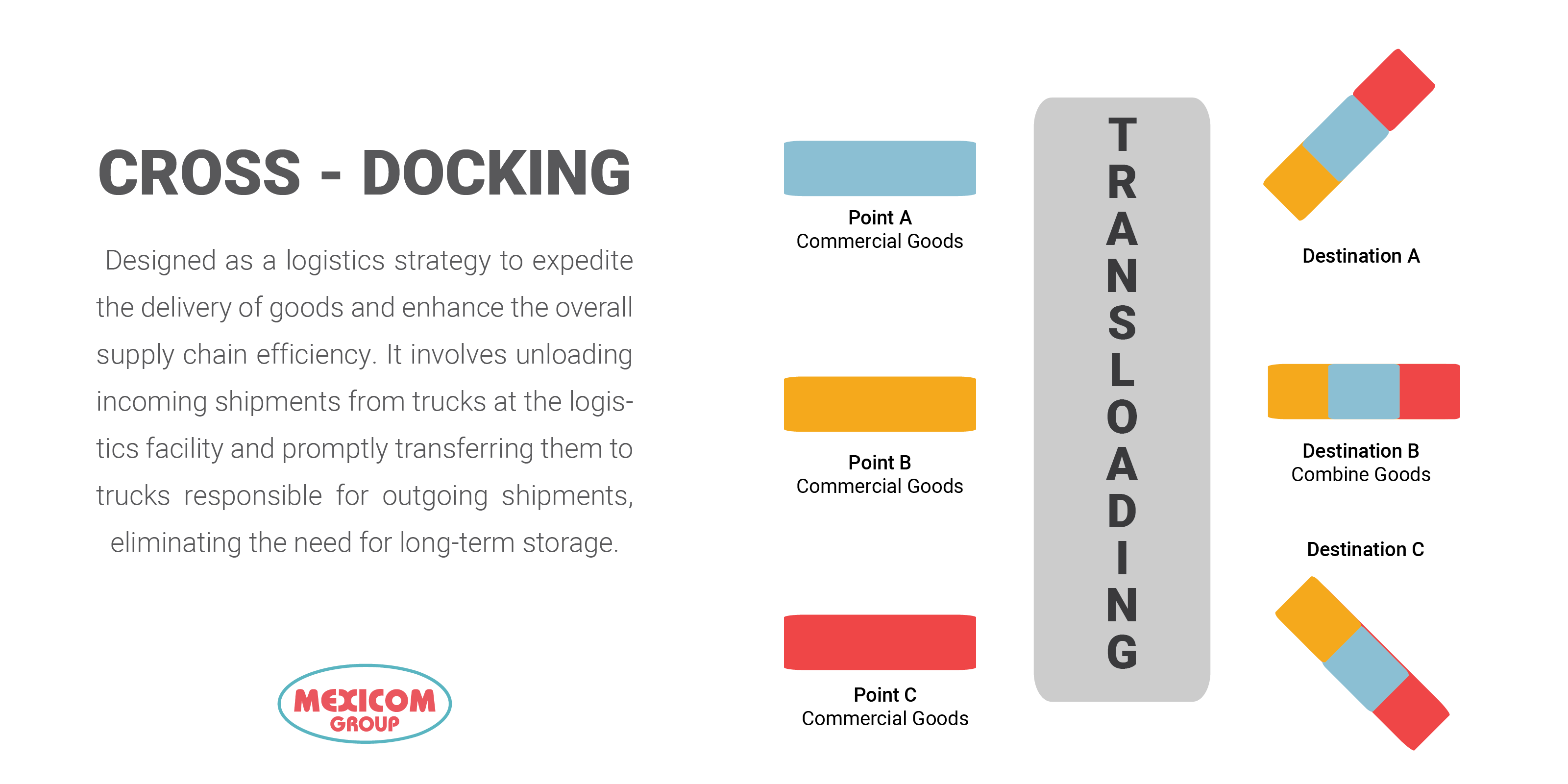

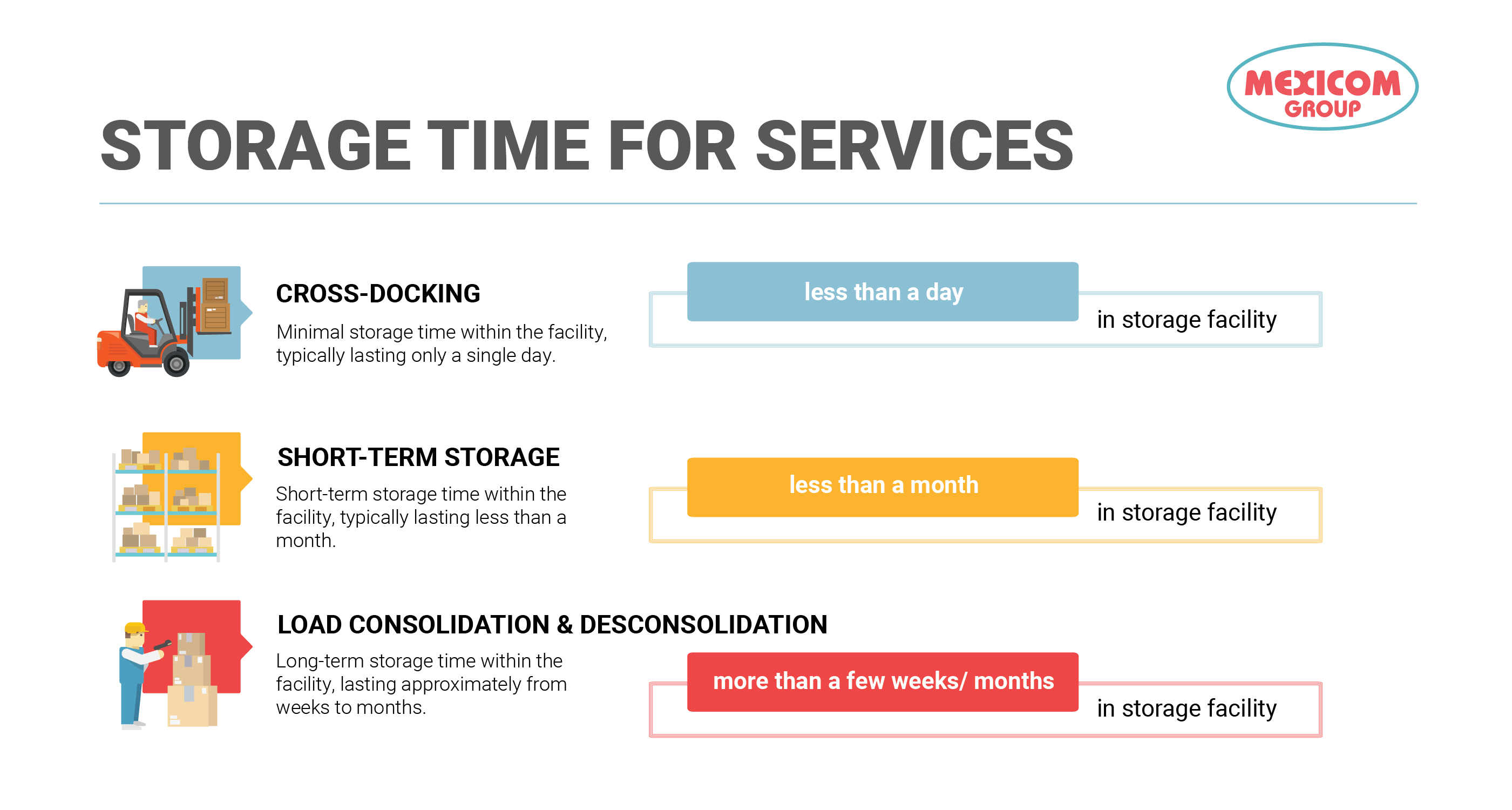

CROSS-DOCKING

- Cross-docking is designed as a logistics strategy to expedite the delivery of goods and enhance the overall supply chain efficiency. It involves unloading incoming shipments from trucks at the logistics facility and promptly transferring them to trucks responsible for outgoing shipments, eliminating the need for long-term storage.

- In this service, the commercial goods get broken down into smaller lots, and strategically rearrange items for efficient distribution to the end customers. Knowing all about cross-docking can be extremely beneficial to selecting the best and right solution for your business.

- Successful cross-docking necessitates effective coordination among a company’s supply chain, including suppliers and freight carriers. In order to deliver the product faster, reduce warehouse space, enhance inventory control, and lower transportation and warehouse costs.

- Our cross-docking procedure in Mexicom USA facilitates a ‘just-in-time’ strategy, guaranteeing the prompt delivery of products to their designated destinations. This swift pace enhances the agility of your supply chain, allowing you to promptly respond to market demands and maintain a competitive edge.

Our team at Mexicom USA is committed to delivering a smooth, cost-effective, and environmentally conscious solution. By opting for a partner dedicated to your success, your supply chain will benefit from efficiency, speed, and overall success in the dynamic realms of logistics and commerce.

Cross-docking is distinguished by its minimal storage time within the facility, typically lasting only a single day. This swift and efficient process ensures that goods move through the facility promptly, contributing to the overall agility and responsiveness of the supply chain.

> less than a day

Load Consolidation and Deconsolidation

Consolidation

- Involves the merging of various smaller incoming shipments to a facility to form a single-larger outbound load.

- The objective is to reduce shipping costs, given that transporting one substantial load is generally more economical than shipping multiple smaller loads.

- Consolidation involves an inventory process where all the products within a load are gathered before merging. This recapitulation of all products is frequently conducted using the warehouse management system for enhanced accuracy and efficiency.

- The implementation of a warehouse management system to the inventory proves beneficial for companies.

The load consolidation service at Mexicom USA, seamlessly combines numerous smaller inbound product loads from diverse sources into a unified outbound full truckload at our dock facility. This strategic approach streamlines logistics, optimizes transportation processes, and results in heightened cost-efficiency while minimizing transit times.

Desconsolidation

- Deconsolidation represents the inverse of the consolidation approach. In this method, a sizable incoming load is partitioned at the logistics facility into numerous smaller shipments destined for individual customers.

- In this service, is also essential the use of a warehouse management system to provide efficient inventory supervision.

Mexicom USA proficiency in deconsolidation guarantees accurate and efficient distribution of goods, seamlessly meeting specific customer requirements with our meticulous processing, sorting, and preparation for final delivery.

Load consolidation and deconsolidation are distinguished by their long-term storage time within the facility, lasting approximately from weeks to months. The time depends on the amount of the load and time to properly do the whole inventory.

< more than a few weeks/months

Short-Term Storage

- Provide businesses and companies with a flexible and convenient solution for their temporary cargo storage needs.

- Flexible and reliable storage options in streamlining transportation logistics, navigating transit delays, and optimizing supply chains.

Mexicom USA provides a service that offers flexible and convenient solutions for businesses and companies in need of temporary storage for their cargo. We ensure our facility is strategically positioned to establish a centralized hub for the temporary storage of goods during transit.

Short-term storage is distinguished by its short-term storage time within the facility, typically lasting less than a month. Taking advantage of the safety of our warehouse.

> less than a month

Upcoming Mexicom USA Warehouse in Laredo, TX

The destination for the best storage solutions arrives in Laredo, Texas. This facility is being designed to meet all your possible storage needs. Whether short-term storage, load consolidation, deconsolidation, or cross-docking, our warehouse will be your operations hub for seamless and efficient operations in the Laredo area.

Special Features

- Hazmat Certified Storage

- Emergency Eye Shower Setup

- Emergency Full Shower Setup

- Trained Team to Deal with Totes, Pallets & Sacs

- Special Zones to Deal with, and Fix Damages

- Close to Columbia Crossing Bridge

Highlights

- Total Space 4.009 Acres

- Warehousing Space 43,000 SQ/Ft

- Head clearance 24 Feet

- 2 Isles of racks +8 storage zones (+2 Hazmat)

- Advanced Electric-Powered Ventilation System

- HD Video Surveillance 24/7

- 17 Loading Docks with Levelers + Ramp

- Controlled Access

- Parking Space for 60 Trailers

- Fully covered with High-Speed Secure Wi-Fi

- 2500 SQ/FT of offices

Warehousing Management System used at Mexicom’s USA facility

We use the Warehouse Management System (WMS) to enhance the efficiency of all our warehousing solutions. This advanced system plays a pivotal role in optimizing various aspects of our operations, ensuring accuracy, real-time tracking, and seamless coordination. From inventory management to order fulfillment, our WMS contributes to the overall efficiency of our facility, allowing us to provide top-notch warehousing solutions that align with the diverse needs of our clients.

- Cloud Based State of Art

- Pictures for all Transloding Activity

- Receipts and Shipments Notices to Customers with Pictures

- Manager Inventory from Pallet up to SKU Level

- Fully Automated

- Advanced Reporting System as per Client Requirements

- Connect to TMS System of the Group

In conclusion, within the ever-evolving landscape of logistics and commerce, the significance of warehousing solutions cannot be overstated. These solutions, integral to optimizing supply chains and ensuring seamless operations, see a warehouse not merely as a storage space but as an efficient distribution network. As businesses navigate the diverse offerings provided by many warehouses, the key lies in choosing the right solution for specific needs. Understanding all the warehousing services. As businesses navigate the business of logistics, and supply chain operations, choosing the right warehouse solution will be beneficial to both logistics panthers and businesses looking for those solutions.

SOURCES:

https://www.netsuite.com/portal/resource/articles/inventory-management/cross-docking.shtml

https://dfreight.org/blog/warehousing-solutions-a-comprehensive-overview/#:~:text=Warehousing%20solutions%20are%20systems%20that,and%20organizing%20their%20inventory%20efficiently

https://www.sap.com/products/scm/extended-warehouse-management/what-is-a-wms.html#:~:text=WMS%20meaning%3A%20a%20warehouse%20management,until%20the%20moment%20they%20leave