How to cultivate resilience in your supply chains

The performance of individuals and organizations must continually adjust to current conditions. In this post, we will review what Harvard business review and Deloitte teach us about how to cultivate resilience in a supply chain.

What is resilience?

Resilience is defined as the capability of a strained body to recover its size and shape after deformation caused especially by compressive stress. It is also the ability to recover from or adjust easily to misfortune or change.

In the business world, resilience is the capacity of companies to sustain key business processes and functions despite adverse impacts upon their activities.

3 ways to developpe resilience

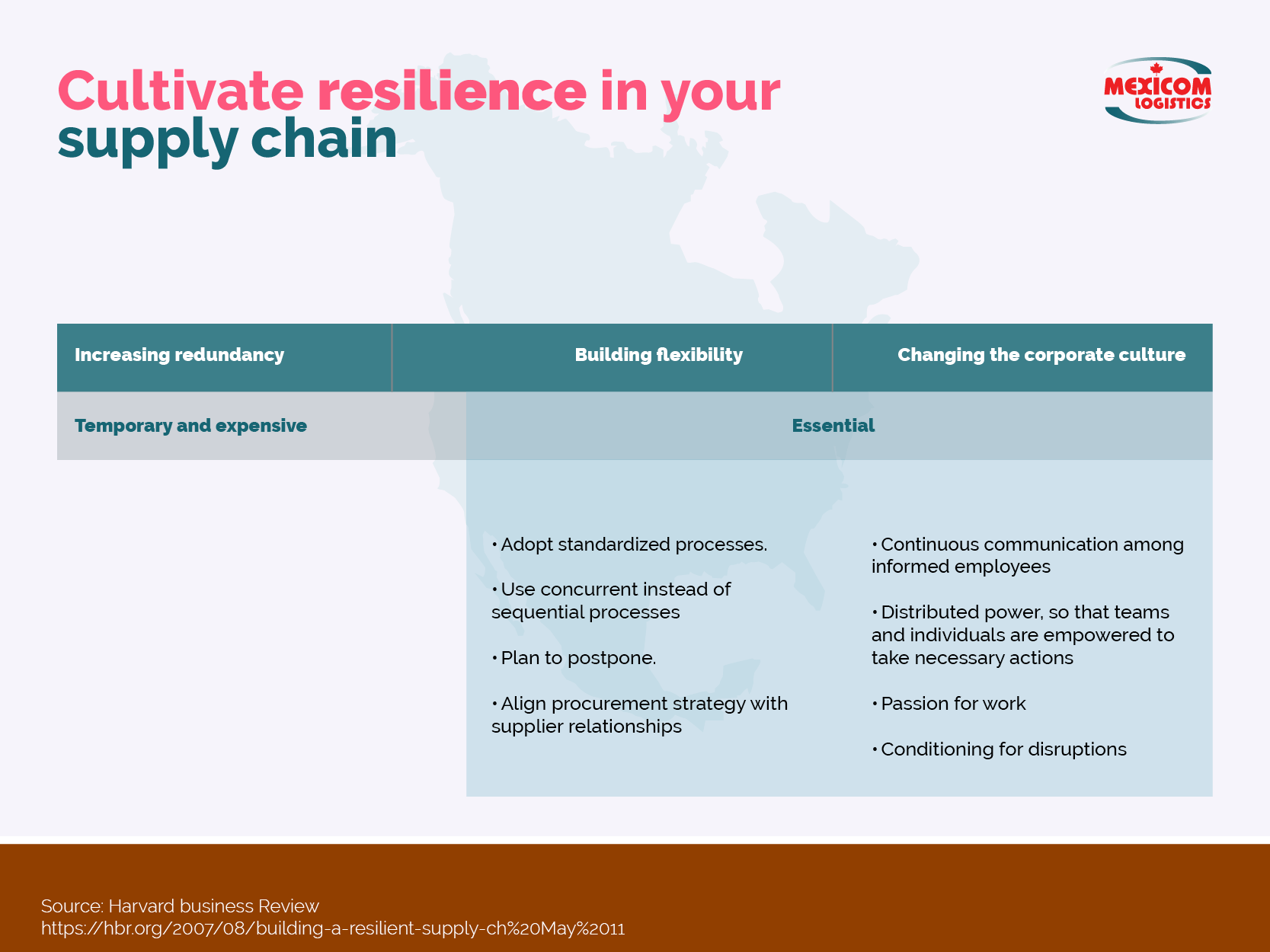

According to Harvard Busines Review, companies can develop resilience in the three main ways:

- Increasing redundancy

- Building flexibility

- Changing corporate culture

One the one hand, given that resources and money are limited, the first way, increasing redundancy, is temporary and expensive. On the other hand, building flexibility and changing corporate culture are two essential ways to cultivate resilience within an organization.

Building flexibility

In order to allow for flexibility, a business should:

Adopt standardized processes:

- Use interchangeable and generic components in many products.

- Develop identical processes across the company

- Cross-training employees.

Use simultaneous processes

Keep products unfinished and generic and complete them once more information is available.

Monitor suppliers and maintain a deep relationship with them.

Cultural change

Keep all employees informed and aware of the business strategy.

Distribute power, so that employees are empowered to take action.

Passion for work. Successful companies engender a sense of the greater good in their employees.

Cultivating Resilience in your supply chain

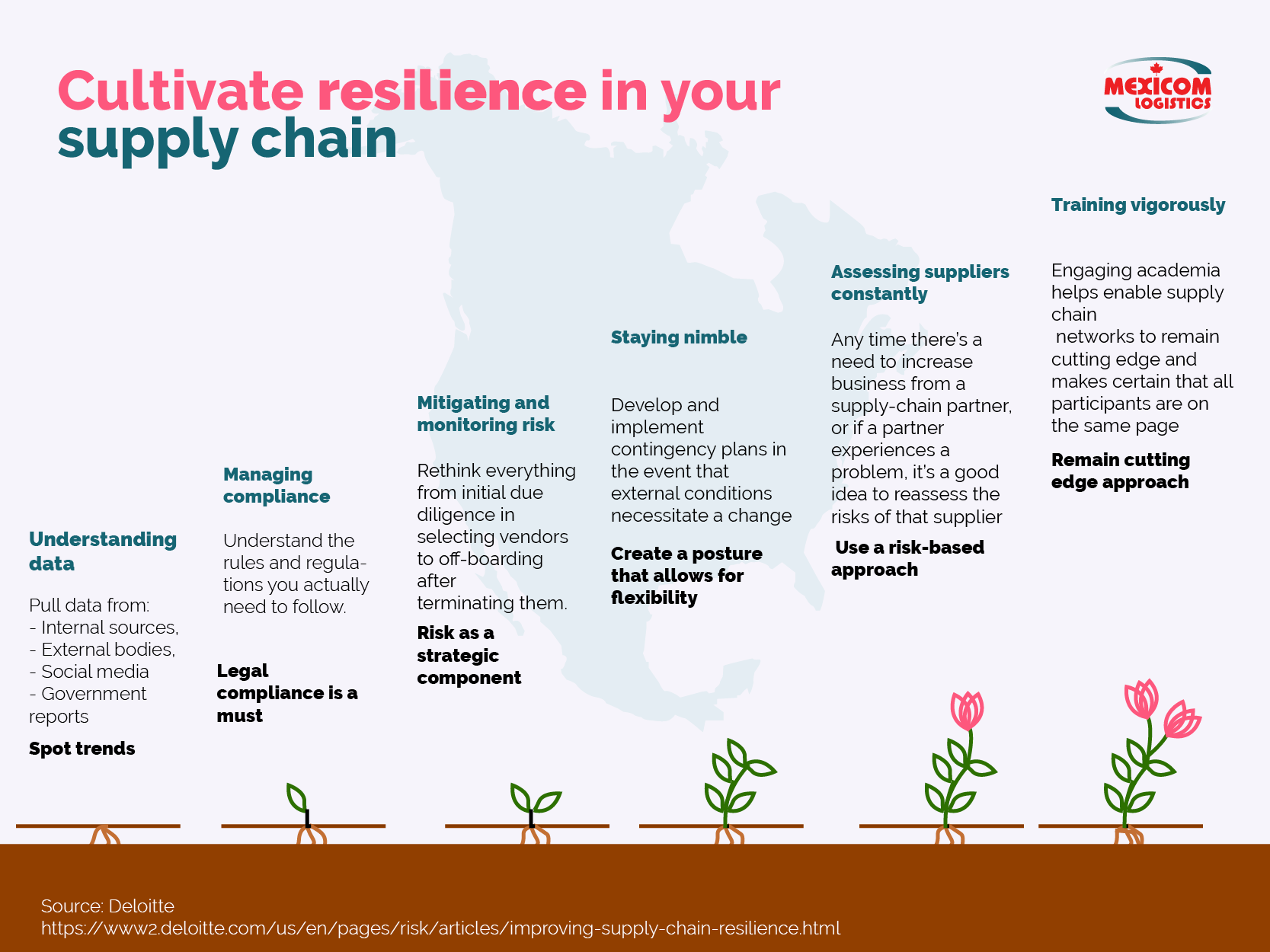

In a recent report, Deloitte identifies areas that can help businesses to build supply chain resilience and face the threat of disruption. Here, we present an infographic and a brief summary of that report.

1- Understanding data

Pull data from:

– Internal sources,

– External bodies,

– Social media

– Government reports

And other sources to spot trends in your industry.

2- Managing compliance

Understand the rules and regulations you actually need to follow. Remember, legal compliance is a must.

3- Mitigating and monitoring risk

Rethink everything from initial due diligence in selecting vendors to off-boarding after terminating them.

Use risk as a strategic component.

4- Staying nimble

Develop and implement contingency plans in the event that external or internal conditions necessitate a change. this will help you create a posture that allows for flexibility.

5- Assessing suppliers constantly

Any time there’s a need to increase business from a supply-chain partner, or if a partner experiences a problem, it’s a good idea to reassess the risks of that supplier. Use a risk-based approach to assess suppliers.

6- Training vigorously

Engaging academia helps enable supply chain networks to remain cutting edge and makes certain that all

participants are on the same page.

Sources:

Disaster Resilience: An Integrated Approach, edited by Douglas Paton, David Moore Johnston, Charles C Thomas Publisher. https://books.google.ca/books?hl=en&lr=&id=B-1VGNdM8lkC&oi=fnd&pg=PA249&dq=resilience+in+business&ots=SVARKMKC5H&sig=6lPrLfeFkiENcdHE5fnZjLozURQ#v=onepage&q=resilience%20in%20business&f=false

https://www2.deloitte.com/us/en/pages/risk/articles/improving-supply-chain-resilience.html

https://hbr.org/2007/08/building-a-resilient-supply-ch%20May%2011