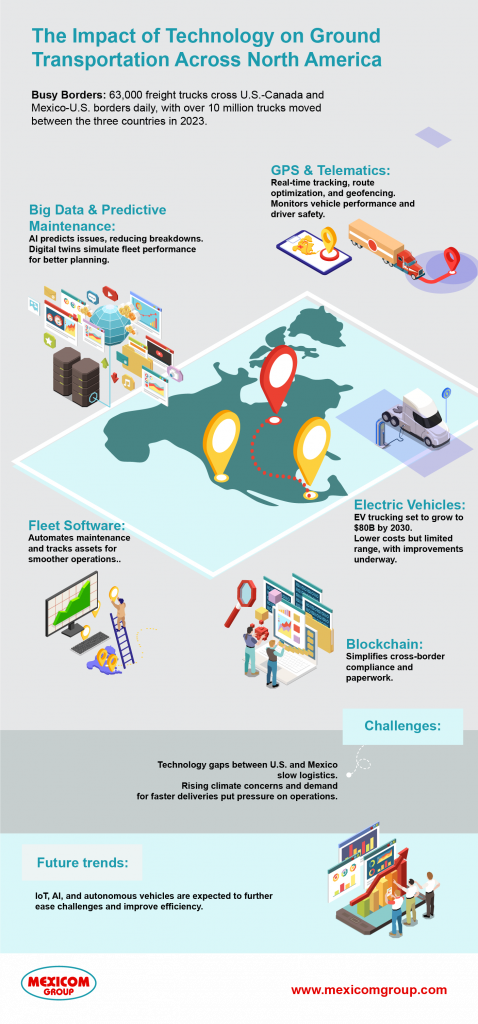

The Impact of Technology on Ground Transportation Across North America: From GPS to Electric Vehicles

The U.S.-Canada and Mexico-U.S. borders are very busy places. The U.S. Department of Transportation estimates that 63,000 freight trucks cross these borders every single day.

As you’d imagine, operations of this scale are tricky to navigate. Even the smallest component failure can lead to long delays, while a single case of driver negligence increases the risk of non-compliance with any one of three sets of regulations.

In this landscape, innovation has been the only constant. Logistics companies are increasingly looking to invest in the next big tool, technology, or technique to streamline services, reduce downtime, and raise profits. Here are the most prominent technologies shaping ground transportation across North America today.

Tracking Performance with GPS and Telematics Devices

Over the years, global positioning systems (GPS) have proven to be the biggest source of real-time location data. Satellite tracking has enabled cross-border fleet operators to benefit from improved visibility, smarter route planning, enhanced safety, and more.

GPS allows operators to set up geofences that notify them when a truck passes through a restricted area — such as a border — and take appropriate action. Simultaneously, it allows customers to benefit from live notifications on their shipment status as it moves across long distances. Moreover, GPS systems are a crucial technology driving the growth of telematics, which, apart from live tracking, offer unparalleled insight into:

Vehicle Performance

Telematics sensors and devices keep tabs on and relay crucial fleet performance metrics, such as average speeds, mileage, fuel efficiency, and more. This data is crucial for operators looking to plug productivity gaps and ensure the longevity of a fleet.

Freight Safety

Tracking systems prevent unauthorized vehicle usage and allow fleet managers to keep track of crucial freight in real-time. This includes checking the temperature and status of perishable goods, or — in the worst case — recovering stolen freight, or vehicles.

Driver Habits

Both Canada and the U.S. mandate that trucks be fitted with Electronic Logging Devices — a telematics tracker that records a driver’s hours of service. These devices help enhance driver safety, prevent accidents, and ensure compliance with hours of service regulations, which is especially crucial in the case of long-haul trucking.

In the U.S., for instance, the DOT 70 hour rule prohibits commercial drivers from being on the road for more than 70 hours over an 8-day period. Canada and Mexico have similar restrictions — and while Mexico doesn’t mandate the use of ELDs, all drivers who enter the U.S. must comply with the DOT 70 hour rule.

Preventing Failures with Big Data and Predictive Maintenance

Ensuring fleet uptime is one of the primary goals of any fleet manager. So far, preventive maintenance practices have gone some way in enabling operators to reduce the frequency of failures and breakdowns.

But in recent years, major strides in data collection, AI analysis, and management software have enabled the next step in this progression — predictive maintenance.

Here’s how it works: Operators use machine learning algorithms to make sense of the performance data gathered by telematics sensors to predict issues before they arise. This allows for better maintenance scheduling, fewer failures, and faster deliveries.

Digital Twins for Advanced Predictive Maintenance

Digital twins are a critical technology driving predictive maintenance practices. Fleet operators can leverage these highly detailed models of their fleets to track crucial performance metrics, assess risks, and plan maintenance schedules accordingly.

Furthermore, a digital twin can be used to simulate the performance of a fleet over various road conditions and weather patterns. It can help fleet managers predict road blockages, and plan more efficient routes — all of which are critical to streamlining long-haul cross-border transportation.

Driving Sustainability with Electric Vehicles

The economic impact of ground transportation across North America has clearly been immense. But so has its environmental impact. A substantial share of greenhouse gas emissions on the continent comes from long-haul trucks traversing thousands of miles between the three countries. While telematics and data analysis have helped improve fuel efficiency and take more efficient routes, the only way forward lies in electrification.

And, well, it’s an exciting time for electric truck manufacturers in North America right now. The industry is valued at USD 16.66 billion today but is expected to grow to approximately USD 80 billion by 2030.

While each country has its own regulations and individual climate goals, the electrification of trucks across North America is inevitable as battery-electric vehicles are cheaper to operate and require less maintenance. With that said, there are still some challenges to iron out before complete electrification.

For one, their low ranges have proven to be problematic. It’s estimated that a majority of U.S. trucks drive over 250 miles a day, but most electric trucks only have a range of 150-250 miles. In the coming years, this will slowly change. Already, manufacturers like Volvo have begun presenting electric trucks with ranges of upwards of 450 miles.

As EV infrastructure ramps up across the continent, we can expect the electrification of trucking to have a massive impact on ground transportation across the three countries.

Easing Documentation with Blockchain

There’s a lot of paperwork involved in cross-border trucking, especially on the U.S.-Mexico border, where Mexican drivers must have relevant visas to enter the U.S.

Blockchain ledgers have proven to be extremely valuable in this regard — as they essentially act as a tamper-proof and immutable record of crucial data.

These records not only help drivers navigate various complex regulations across borders, but also reduce administrative errors, facilitate seamless payments, and foster better collaboration between every stakeholder in the supply chain.

- Understanding the Blockchain and its impact on the supply chainThe blockchain technology was originally designed for cryptocurrencies or bitcoins, however, its uses are already being extended to different industries such as logistics and supply chain, [...]Read more

Tying it all Together with Advanced Software

Fleet management software is the glue that ties all these technologies together.

Today’s advanced offerings allow logistics companies to visualize the various threads of data offered by telematics sensors, automate maintenance practices, and live track the location of freight, or a particular asset.

In the future, such software will also prove to be critical in handling electric trucks, as they are complex machines equipped with multiple sensors that collect rich data.

Navigate Technological Advancements in Logistics With Confidence

While the introduction of new technologies has streamlined operations, lowered costs, and lessened workloads, it has brought with it a myriad of challenges as well. For instance, a widening technology gap between carriers and logistics companies in the U.S. and Mexico threatens to slow down operations to a degree. Similarly, rising climate concerns combined with the pressure to make faster deliveries have also taken a toll.

As we move into the future, we can expect further advancements in IoT, AI, and machine learning, along with breakthroughs in autonomous vehicles, to fill those gaps, and ease challenges further. Carriers across North America that embrace this change, and invest in their future will likely be the biggest beneficiaries.

This post was written by Graham Perry as a guest writer. He writes on business technology innovation, specializing in logistics supply chain optimization. With expertise in fleet management and transportation technology, his articles empower businesses to navigate the dynamic world of logistics with confidence.