Supplier development part 2: How to move from a Reactive to a Proactive Approach?

In this post, we present the Krause, Handfield &Scannell model to move from a reactive to proactive supplier development and 5 practical recommendations that a group of researchers made to a manufacturing firm to establish a proactive supplier development. The recommendations were developed after performing a cross-case analysis based on data obtained from five manufacturing companies.

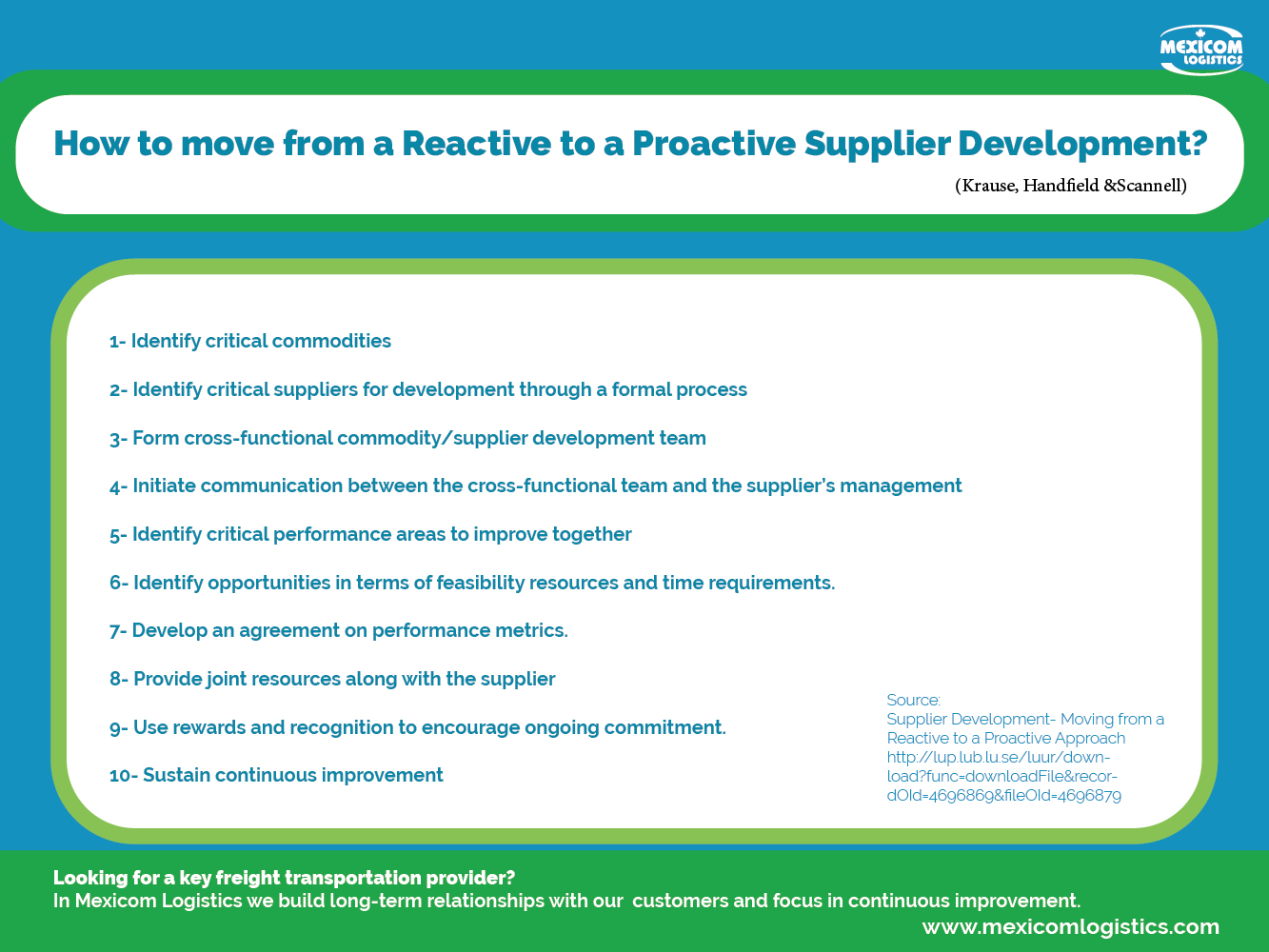

How to move from a Reactive to a Proactive Supplier Development?

There is a very well known Supplier Development Process Model to move from Reactive to Proactive, which consists of 10 phases as follows:

1- Identify critical commodities for development using Pareto analysis or market-driven requirements. Kraljic’s matrix is very useful in this step.

2- Identify critical suppliers for development through a formal process that evaluates performance, quality, service, delivery, technology and environmental performance.

3- Form cross-functional commodity/supplier development team assigned on a long-term or permanent basis to improve the performance of the supply base.

4- Initiate communication between the cross-functional team and the supplier’s management to share information and work together towards a common goal.

5- Identify critical performance areas to improve together with the supplier’s top management.

6- Identify opportunities in terms of feasibility resources and time requirements. Risk evaluation is a useful tool for this step.

7- Develop an agreement on performance metrics. Examples of metrics are percent cost savings, percent quality improvement, percent delivery or cycle time improvement, key product service performance.

8- Provide joint resources along with the supplier and implement supplier development

9- Use rewards and recognition to encourage ongoing commitment.

10- Sustain continuous improvement by creating mile-stones for objectives, updating goals and adopting continuous improvement strategies.

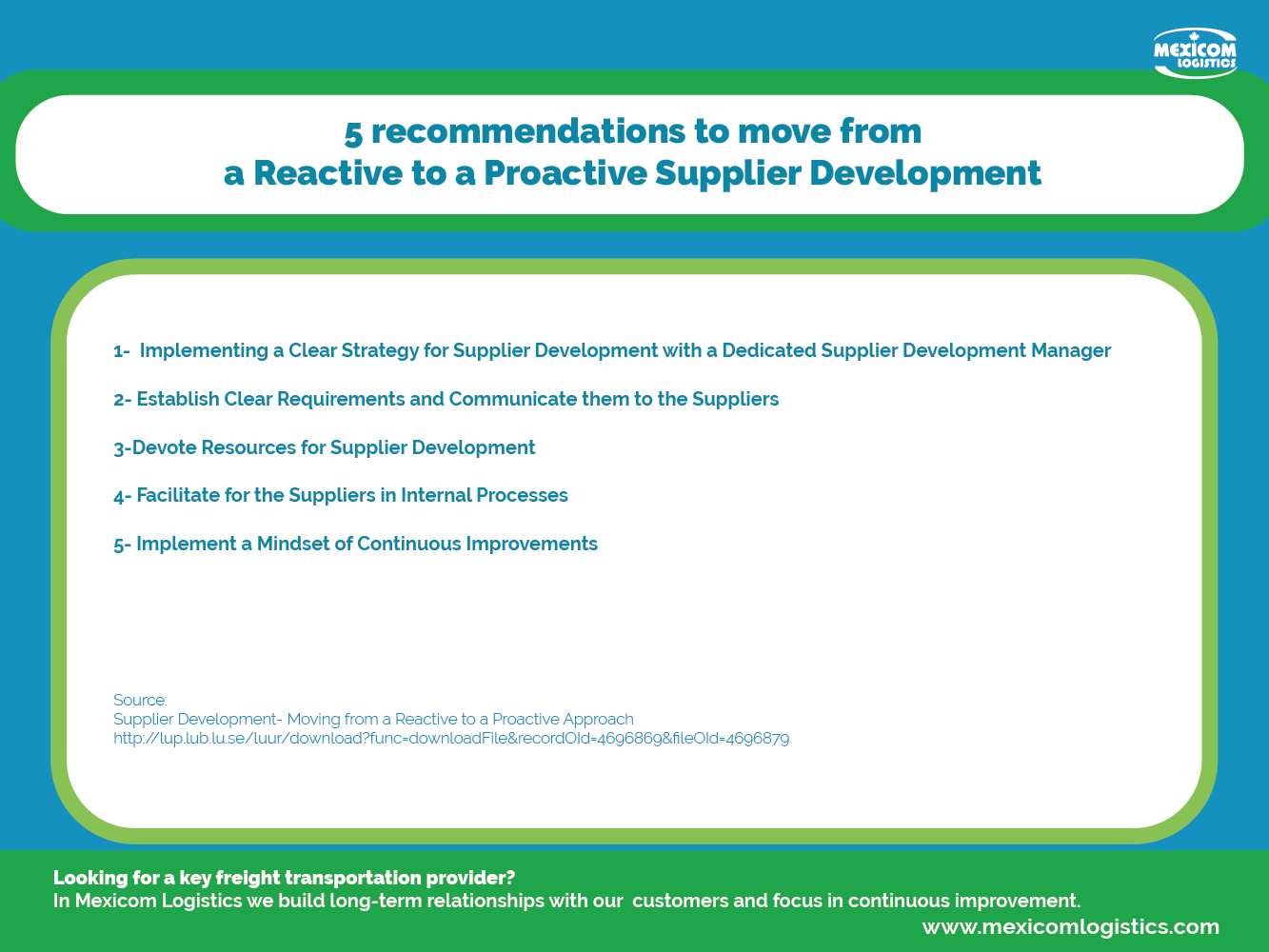

A fresh view on moving from Reactive to a Proactive supplier Development – 5 recommendations

In this section, we will present the recommendations made to a global manufacturer on how to move from a reactive to a proactive approach to Supplier Development. The recommendations were developed by a research group at the Department Industrial Management & Logistics of Lund University after performing a cross-case analysis based on data obtained from five case study manufacturing companies. Read the article here

Actions recommended by the researches to establish a more proactive approach of supplier development:

Recommendation One – Implementing a Clear Strategy for Supplier Development with a Dedicated Supplier Development Manager

They recommended assigning a dedicated person with a holistic view to implement the strategy. This person should be part of the management level.

At this step, it is important to make a classification of the suppliers and effort should vary between the categories of suppliers. A good tool for supplier’s classification is the Kraljic’s matrix.

Non-critical suppliers need a good contract and competition through multiple sourcing while the relationship with strategic suppliers should aim for partnership.Strategic suppliers should receive most development efforts to achieve partnership. It is also vital to see the supplier development as a mutual work together with the suppliers.

Recommendation Two – Establish Clear Requirements and Communicate them to the Suppliers

It is important to maintain clear communication with the suppliers so they have a good understanding of what is required from them and how.

Recommendation Three – Devote Resources for Supplier Development

The company needs to invest in the development of its suppliers. For example, dedicate resources on education and training of suppliers.

Recommendation Four – Facilitate for the Suppliers in Internal Processes

Increasing the supply base performance involves the company facilitating processes for their suppliers. To do so, sometimes the company needs to improve its own internal processes.

Recommendation Five – Implement a Mindset of Continuous Improvements

The method of continuous improvement should be implemented as a permanent solution at the suppliers and at the focal company.

Sources

https://www.academia.edu/14626715/PROACTIVE_PROCUREMENT_AND_PURCHASING_STRATEGIC_OPERATIONS_FOR_A_COMPETITIVE_EDGE

http://lup.lub.lu.se/luur/download?func=downloadFile&recordOId=4696869&fileOId=4696879

This article is very interesting which is worth reading it . Thanks for information