Case study- Things to take into consideration when transporting mobile machinery on flatbeds

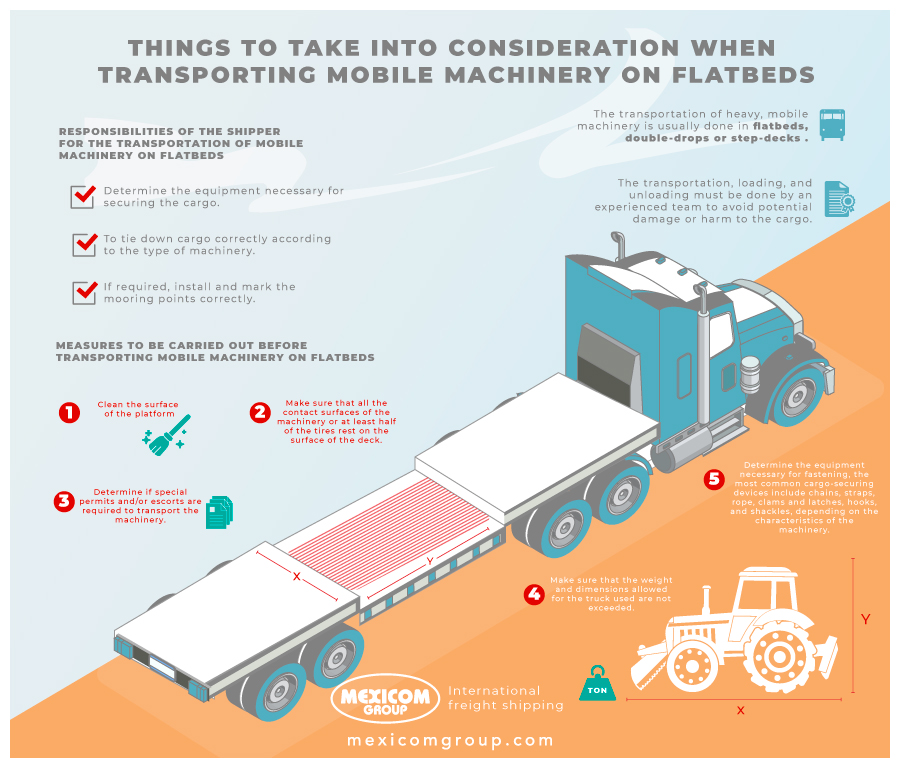

The transportation of heavy, mobile machinery, such as cranes, bulldozers, excavators, backhoes, and forklifts, among other equipment, is usually done in flatbeds, double-drops or step-decks. The transportation, loading, and unloading must be done by an experienced team to avoid potential damage or harm to the cargo. In this post, we share with you the important considerations to take into account when transporting or hiring a freight service to transport mobile machinery on flatbeds

Responsibilities of the shipper for the transportation of mobile machinery on flatbeds

- Determine the equipment necessary for securing the cargo.

- To tie down cargo correctly according to the type of machinery.

- If required, install and mark the mooring points correctly.

Measures to be carried out before transporting mobile machinery on flatbeds

- Determine the equipment necessary for fastening, the most common cargo-securing devices include chains, straps, rope, clams and latches, hooks, and shackles, depending on the characteristics of the machinery. If required, install and mark the mooring points.

- Clean the surface of the platform before placing the mobile machinery to ensure that it does not contain oil, water, grease, ice, and/or other elements that prevent the friction of the machinery with the platform.

- Make sure that all the contact surfaces of the machinery or at least half of the tires rest on the surface of the deck. In case the mobile machinery exceeds the surface of the truck, support must be used.

- Make sure that the weight and dimensions allowed for the truck used are not exceeded. You can take a look at the guide of dimensions and weights for flatbeds here.

- Determine if special permits and/or escorts are required to transport the machinery. The type of permit will depend on the route from the origin to the destination.

The entire surface of the mobile machinery must rest on the deck

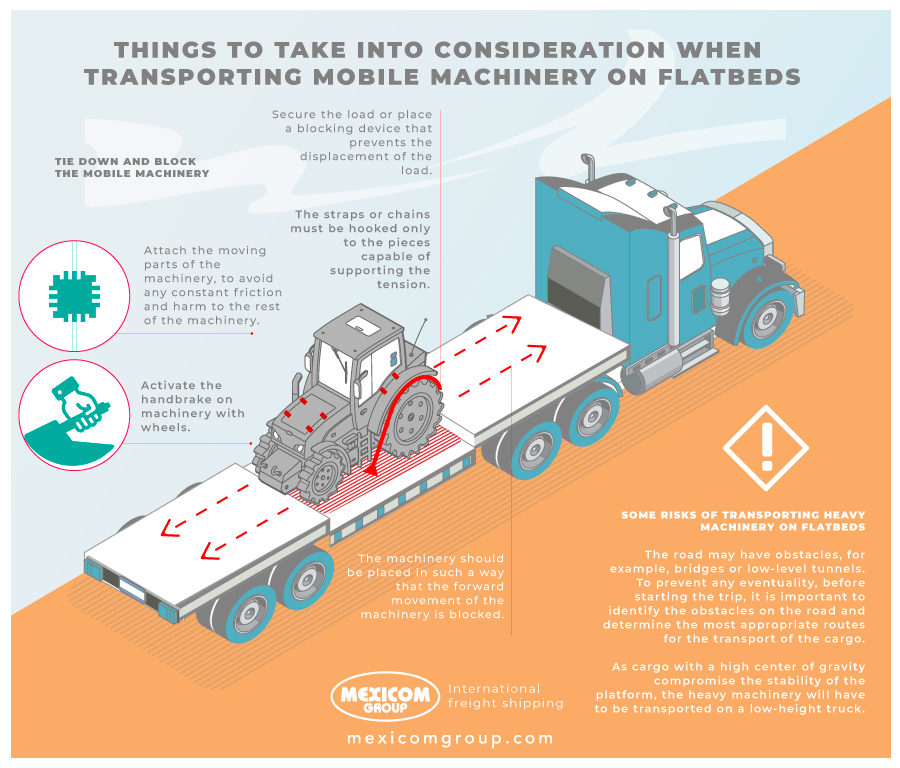

Tie down and block the mobile machinery

- If possible, the machinery should be placed in such a way that the forward movement of the machinery is blocked.

- Secure the load or place a blocking device that prevents the displacement of the load to minimize the effect of jolts caused by road irregularities. If possible, block the suspension elements of the machinery because all the movements of the truck are transmitted and amplified to the tires or to the suspension elements of the mobile machinery.

- Activate the handbrake on machinery with wheels. Sometimes, the effectiveness of the handbrake is reduced if there is not enough friction between the machinery and the deck of the truck in which it is transported, so it is important to also strap down cargo or place blockages that act as an additional brake.

- The straps or chains must be hooked only to the pieces capable of supporting the tension. The straps should not be attached to parts of the machinery that are susceptible to breakage or damage.

- Attach the moving parts of the machinery, to avoid any constant friction and harm to the rest of the machinery.

Cargo secured with chains when transporting mobile machinery in a double-drop

Some risks of transporting heavy machinery on flatbeds

The road may have obstacles, for example, bridges or low-level tunnels. To prevent any eventuality, before starting the trip, it is important to identify the obstacles on the road and determine the most appropriate routes for the transport of the cargo.

As cargo with a high center of gravity compromise the stability of the platform, the heavy machinery will have to be transported on a low-height truck.

Being a load with a high center of gravity, the mobile machinery is transported on a low height truck

If you have questions about the transport of mobile, heavy machinery or other equipment on flatbeds, contact us.

If you want to transport cargo between Mexico, America and Canada on a flatbed, double-drop or step-deck, request a quote.

That’s pretty good.

Thanks for sharing!

I read this blog and I really liked it, you are doing your job well.